Diamond grinding tools for sapphire processing

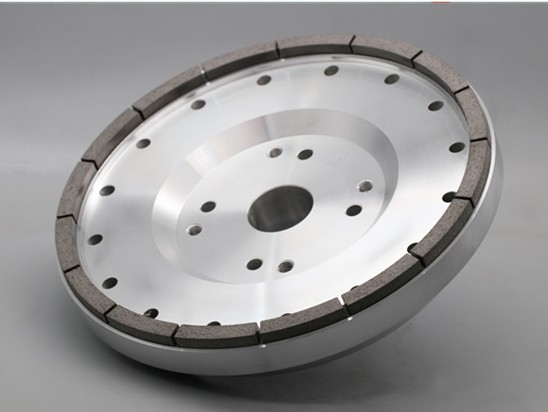

Cylindrical grinding wheel

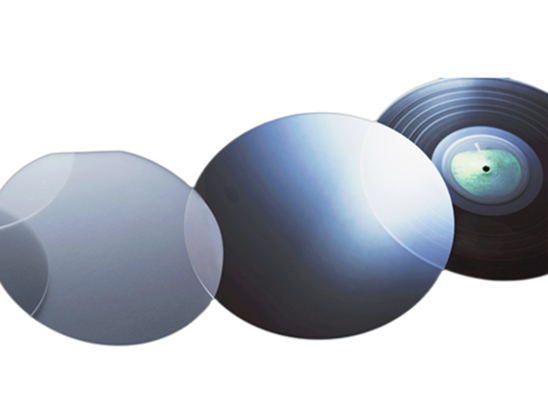

Back grinding wheel

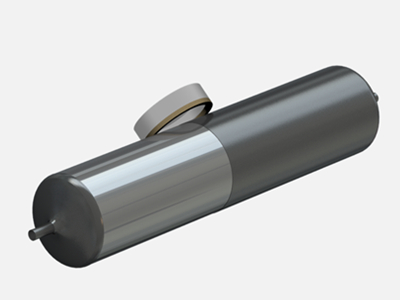

Diamond band saw for cutting sapphire

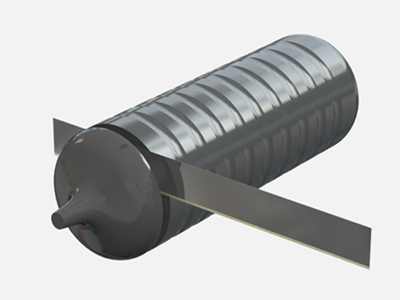

Diamond edge grinding wheel for sapphire

Diamond polishing pate, diamond compound, diamond polishing pad

The main component of sapphire is alumina (Al2O3), Mohs hardness is 9, second only to the hardness of superhard materials, it is high temperature resistance, good thermal conductivity, high hardness, infrared permeability, good chemical stability. It is widely used in many fields of industry, national defense and scientific research. It is the window material of infrared device, missile, submarine, satellite space technology, detection and high-power laser, high-quality optical material, wear-resistant bearing material and substrate material. Sapphire has the characteristics of hard and brittle, and the price is expensive. In the process of processing, it usually requires high precision, fast processing efficiency, low material loss and clean working environment. Diamond is the material with the highest hardness and strongest wear resistance in nature, so diamond tools are the best choice for processing sapphire materials.

Sapphire is the corundum gem in addition to Ruby (Ruby), other colors corundum gem general name, which includes blue, sky blue, blue green, green, yellow, orange, brown, gray, black and colorless and other colors, Sapphire color by its chemical composition containing titanium, iron, vanadium and other trace elements caused.

Diamond tools for sapphire

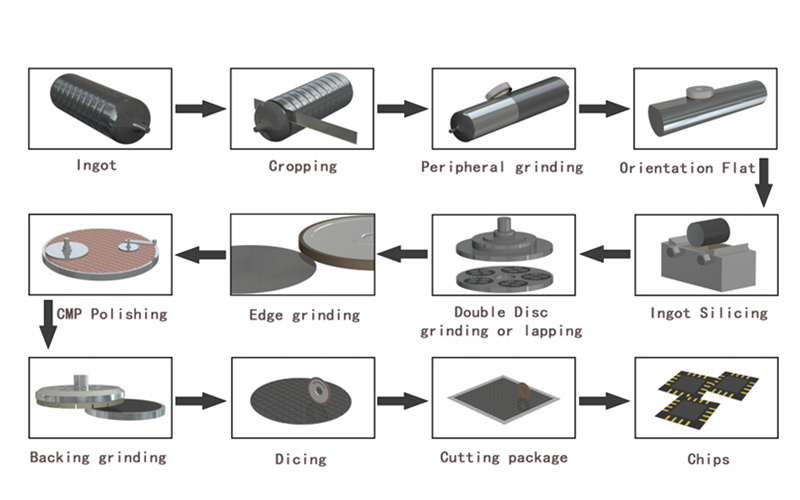

From sapphire crystal ingot to the final sapphire substrate , the following steps are mainly involved:

Seed crystal growth

Using long crystal furnace to grow large size and high quality single crystal sapphire crystal

Seed crystal orientation

Using long crystal furnace to grow large size and high quality single crystal sapphire crystal.

Take crystal bar

Use sapphire bit (high precision bushing bit) to remove sapphire crystal rod from sapphire crystal (including removing head and tail, end face grinding).

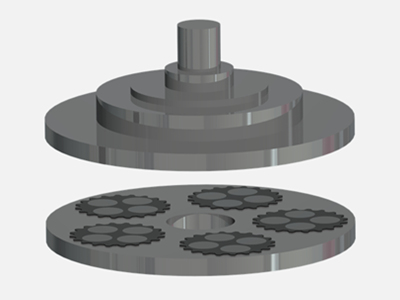

The nesting bit for sapphire processing is generally composed of three parts: threaded joint, pipe body and tool head. Among them, the precision requirements of the nesting bit head and drill pipe are:

1) The outside diameter of the 2 “, 4 “and 6” bit heads shall be D±0.05mm, the inside diameter of the tool heads shall be D±0.05mm, and the thickness of the tool heads shall be ≤2.8mm, with a thickness tolerance range of ±0.05mm;

2) the outer diameter of the matrix is D±0.05mm, the inner diameter of the matrix is D±0.05mm, the thickness of the matrix is less than 1~2mm, the tolerance range is ±0.05mm, and the effective length of the matrix is 120~440mm;

3) The inner gap between the tool head and the matrix is 0.45±0.05mm, and the outer gap is 0.45±0.05mm;

4) 2 inch sleeve drill runout ≤0.05mm, 4 inch ≤0.08mm, 6 inch ≤0.10mm.

Head and tail cutting: head and tail cutting with metal binder cutting pieces, diamond band saw, etc.

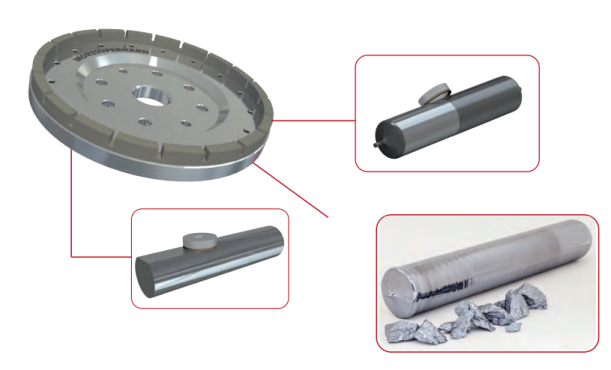

Roll grinding

Using resin diamond cylindrical grinidng wheel or metal diamond cylindrical grinding wheel to carry out the crystallization direction of the crystal bar flat grinding, the outer diameter grinding, to obtain the accurate accuracy of the outer circle size.

Sapphire cylindrical grinding: crystal to flat grinding, mainly use resin bond diamond grinding wheel, coarse grinding particle size of about 100#, 200# fine grinding, resin base has a certain elasticity, play the role of polishing, the workpiece quality is good.

Crystal bar cylindrical grinding wheel

Metal or hybrid bond diamond wheel is used to cylindrical grinding the crystal rod to achieve the required diameter and roundness. Moresuperhard cylindrical diamond grinding wheel has good retention, high grinding efficiency and less dressing times.

Cutting

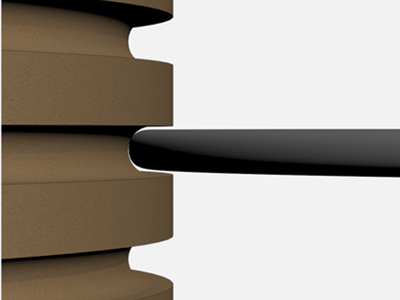

Diamond band saw blade is a kind of composite steel belt inlaid with diamond, the hardest material in the world, on a high quality imported spring steel matrix, which can cut any non-metallic, super hard, brittle materials.

Moresuperhard provide electropalted diamond band saw with excellent cutting surface, the highest level of precision at high cutting speeds and performance and high efficiency to cut the sapphire crystal rod into thin wafers. The electroplated diamond abnd saw has three tooth edge for selection: Continuous Shape, Segmented Shape(half-moon shape) and Serrated Shape.

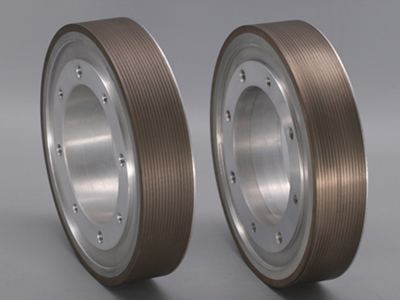

Grinding and lapping

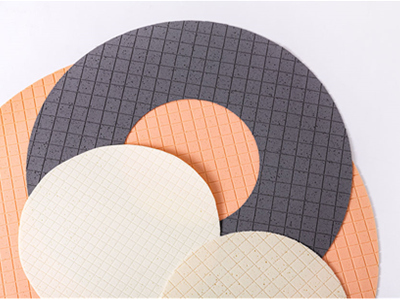

Remove the chip cutting damage layer caused by slicing and improve the wafer flatness. It is divided into coarse grinding and fine grinding, and the abrasive products mainly include diamond double sided grinding disc, PU polishing pad, diamond paste and so on.

CMP polishing improves wafer roughness by CMP polishing, and makes its surface reach epitaxial wafer epitaxial precision. Polishing pad and polishing compound are often used, suitable for precision grinding and polishing of silicon carbide, silicon nitride, gallium arsenide and other semiconductor materials.

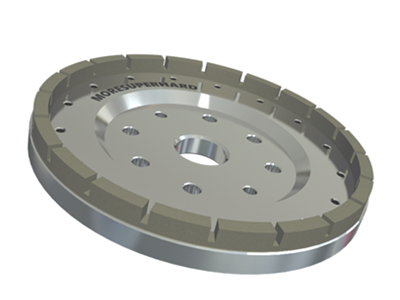

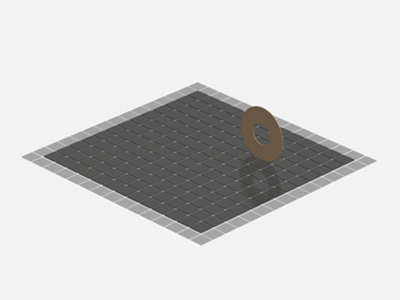

Chamfering sapphire

Metal bond diamond edge grinding wheel is used to trim the wafer edge into an arc shape to improve the mechanical strength of the wafer edge and avoid defects caused by stress concentration. The 45 degree chamfering Angle is 0 ~ 0.2mm.

Chamfering grinding wheel is metal bonded diamond grinding wheel, common size: 1FF1V/9 202*20*30*2.5, Moresuperhard metal diamond edge grinding wheel has high toughness and strength, high groove precision, long service life.

Polishing tools

On the premise that the wafer has a certain strength, the thinning wheel is used to control the wafer thickness, the wafer roughness is improved by polishing, and the surface reaches epitaxial wafer epitaxial precision. CMP polishing fluid is often used.

high precision detectorchecks wafer (flatness, surface dust particles, etc.) to meet customer requirements

-Electroplated diamond grinding heads are also used for drilling contour machining.

–Back grinding wheel for sapphire substrate

–CMP polishing pad, dressing tool

-Diamond paste and diamond compound

Packaging process

It mainly includes the following steps: substrate → substrate → evaporation etching → heat treatment → thinning on the back → grinding and polishing → scratch test → solid crystal → line packaging → cutting → test. The main abrasive products involved are ultra-thin diamond dicing blade, diamond back grinding wheel, diamond compound, diamond paste, etc.

Diamond dicing blade

The ultra-thin diamond dicing blade used in the sapphire industry is mainly divided into two types of bond: metal diamond dicing blade and resin diamond dicing blade.

Moresuperhard provide diamond dicing blade and diamond hubless dicing blade.

The diamond particle size is 270#-600#. Common specifications and models are 1A8, 58*0.2*40; 58 * 0.15 * 40; 56 * 0.1 * 40; 56 * 0.15 * 40, etc.

Related Products

-

Back Grinding Wheel for LED Substrate

Back Grinding Wheel for LED Substrate

-

Edge Grinding Wheel, Silicon Wafer Chamfering

Edge Grinding Wheel, Silicon Wafer Chamfering

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

Si/SiO2 Wafer

Si/SiO2 Wafer

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon Wafer

-

Diamond Dicing Blades For Wafer Scribing

Diamond Dicing Blades For Wafer Scribing

-

Metal bond diamond cutting wheel , steel core with copper plated is used for grooving and cutting carbide,optics glass, sapphire, ceramics , magnetic materials and semiconductor material

Metal Diamond Wafer Blade with Copper Plated

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.