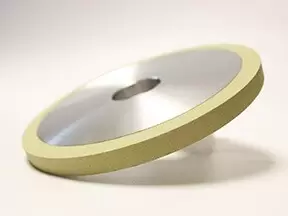

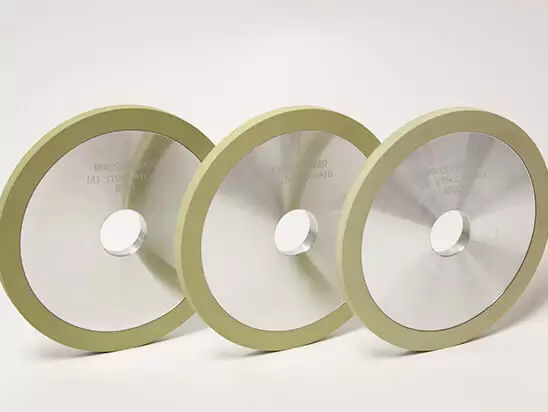

Ceramic Diamond Bruting Wheel for Natural Diamond Polishing

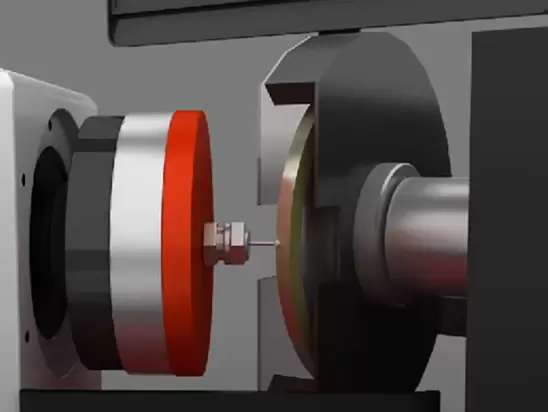

Diamond bruting wheel for girdling, polishing and bruting natural diamond, gemstone, jewel, agate.

Bonded: ceramic / vitrified bond

Model: 1A1 diamond wheel

CNC Bruting Machines: EOS Bruting Machine, Adri Machines And Discron Machine, Etc.

Description of ceramic diamond bruting wheel

Diamonds form only in hot and high-pressure conditions about 100 miles below the Earth’s surface. The diamond’s carbon atoms bond roughly the same in all directions.

When diamonds are mined from the earth, it does not look like what we see in stores. The process of transforming natural diamonds into the brilliant and gorgeous stones need five steeps: including planning, cleaving, bruting, polishing and inspection .

Vitrified diamond grinding wheel is mainly used for polishing and bruting natural diamond. It can substitute PCD (polycrystalline diamond) and possess excellent diamond processing performance. Diamond bruting wheel has been proved its superiority in the jeweler processing industry, since it has enjoyed wide popularity in South Africa, Hong Kong, India, Belgium, Israel market, and etc.

Applications of ceramic diamond bruting wheel

Diamond bruting wheel is installed on advanced CNC bruting machines, widely used for polishing and bruting natural diamonds, gemstone, jewel, agate.

Applicable Bruting Machine:

EOS Bruting Machine, Adri Machines And Discron Machine, Etc.

The advantages of diamond bruting wheels

Compared with resin bond wheel and metal bond wheel, vitrified diamond bruting wheel could process at least 2 to 3 times products at the same time.

Not easy to jam and burn the workpiece, good self-sharpening, easy dressing and long life .

High abrasive resistance and abrasive wear is small.

How to choose grain size to polish natural diamond?

Grain size :MD20, MD40, MD60, MD80

MD-20: fine polishing,perfect shining performance and long life for polishing small diamond (10 points- 1carat)

MD-40, MD-60: rough polishing,high efficiency polishing and sharp cutting for big diamond.(1ct ,1.2ct and 1.3 carat,etc)

MD-80: rougher polishing, higher efficiency and sharp cutting for bigger stones.(2 carat and 3 carat,etc)

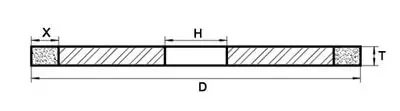

| Model | D (mm) | T (mm) | H (mm) | X (mm) | U (mm) |

1A1 |

80 | 10 | 32 | 8, 10 | |

| 150 | 10 | 32 | 10 | ||

| 155 | 10 | 32 | 10 | ||

| 160 | 10 | 32 | 10,12 | ||

| 170 | 10 | 32 | 10, 12, 14 | ||

| 175 | 10 | 32 | 10 | ||

| 220 | 10 | 32 | 20 | ||

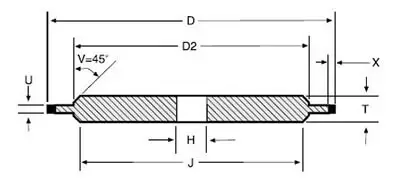

14A1 |

170 | 10 | 32 | 10, 12, 14 | 5 |

| 175 | 10 | 32 | 10, 15 | 5 | |

| Grain size :MD20, MD40, MD60, MD80 | |||||

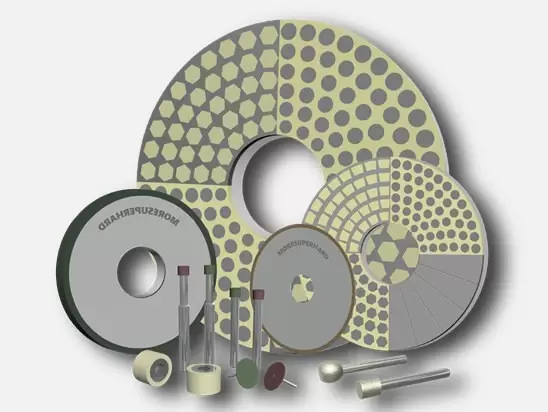

Related Products

-

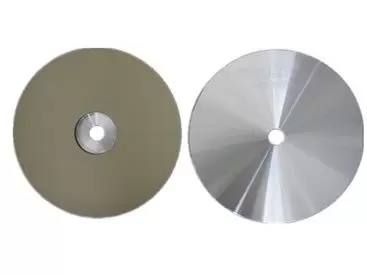

Resin Diamond Lapping Discs for Gemstone surface grinding

Resin Diamond Lapping Discs for Gemstone surface grinding

-

#60 - #3000 Diamond Coated Flat Lap Disc Lapidary

#60 – #3000 Diamond Coated Flat Lap Disc Lapidary

-

Electroplated Flat Lap Diamond Discs of Lapidary Tools

Electroplated Diamond Coated Flat Lap Disc Wheel

-

Diamond bruting wheels are widely used for polishing and bruting natural diamonds, gemstone, jewel, agate.

170/175mm Diamond bruting Wheel for Natural Diamond Polishing

-

Diamond bruting wheel for girdling, polishing and bruting natural diamond, gemstone, jewel, agate.

Ceramic Diamond Bruting Wheel for Natural Diamond Polishing

-

MoreSuperhard offers custom precision ceramic grinding, lapping and polishing service and solution.

High Precision Ceramic Grinding Lapping

-

Moresuperhard resin diamond polishing film can achieve consi...

Resin diamond polishing film

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.