Diamond grinding pad for optical glass

Abrasive: Diamond

Grain: 80, 60, 30, 20, 9, 4, 2, 1 μm

The diamond grinding pad easy installation and removal with pressure-sensitive adhesives (PSA) backing, which can be mounted directly onto the existing grinding disc/polishing machine, such as metallographic sample preparation or polishing IPHONE or IPADS optical glass. There is no need to mix the slurry, saving the polishing time and improving the workshop environment, greatly reducing the cost of mud treatment.

The abrasive is consolidated in the grinding pad to achieve efficient and stable removal rate and improve grinding efficiency > 2x, shorten CMP time>20%, the grinding rate can reach more than 2 times of the same particle size mortar grinding process.

Optimized abrasive layer shape to achieve higher surface quality after optical glass processing, and guarantee superior workpiece plane control performance (TTV, Warp, Bow).

Diamond pads for thinning glass and ceramic over lens use on lapping machine, which can achieve consistent fine surface roughness,high remove rate and long lifetime.

Application of diamond grinding pad

optical glass, compound semiconductor, optical glass wafer, prism, ceramic

Features of diamond grinding pad

High removal rate and smooth fine surface roughness of optical glass

Lower production costs compared to using free abrasives

Shallower subsurface damage layer

Energy saving and environmental protection

| Abrasive | Diamond |

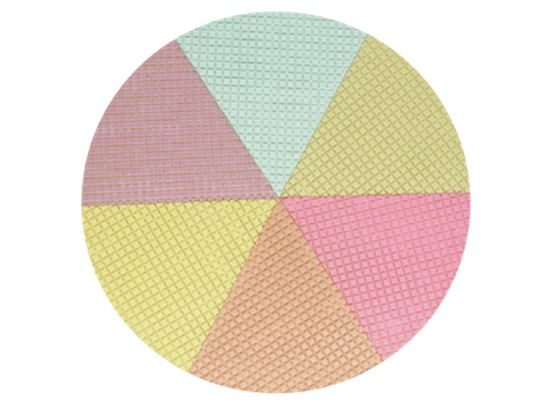

| Structure | Block Type |

| Grain | 80, 60, 30, 20, 9, 4, 2, 1 μm |

| Base Material | PET Composite PC Board |

| Shape | Rectangle, Round |

| Size | φ254,φ300,φ640,φ860,φ880, φ980,φ1120mm |

| Can be cut into square, round shapes, diameter 100,200,300,500mm

According to customer requirements |

|

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.