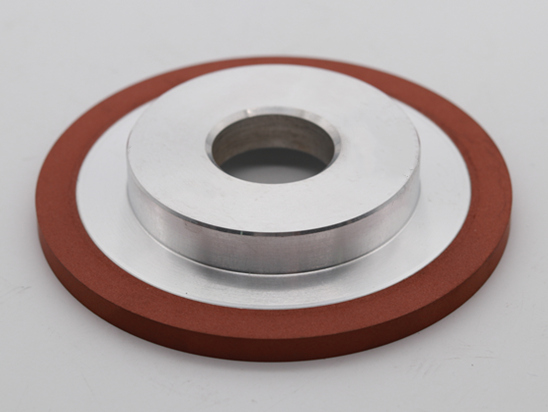

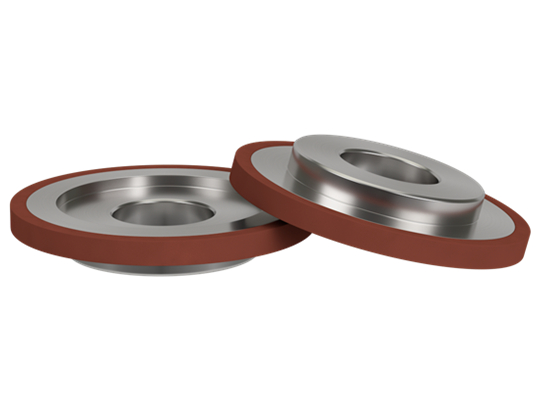

Diamond grinding wheel for Punch machine

Bond: resin ,electroplated bond

Machine: Punch machine

What is punch?

The metal parts on the stamping die in the mechanical tool, also called punches, are installed on the stamping die to perform continuous blanking and punching operations to separate or plastically deform the processed materials, thereby obtaining the required finished products or semi-finished products.

Application of punch grinding machine grinding wheel:

Used for forming, grinding and polishing punching machines

How many types of punch grinding machine?

Punch former is a mechanical device which is installed on the grinder such as milling machine, drilling machine and other machine tools, punch formers are divided into unidirectional punch formers, two-way punch shaper, three-claw punch shaper, electric punch shaper, collet type ER punch shaper, medium punch shaper, large punch shaper and so on.

Punch grinding machines are widely used in various metal processing fields.

Punch ginding machine is mainly used to grind high-precision surface, internal and external cylindrical surfaces, conical surfaces, and spherical surfaces in workpieces. Punch grinding machine is an important process in precision machining, and its advantages are high machining accuracy and a wide range of machining materials.

| Grinding Wheel Size | 100D*25.4H*10/16T*(2-10)U*5W 180D*31.75H*10T*1.5U*5X |

|

| V | 15°, 30°, 45° | |

| Grit | Rough grinding | 46#, 60#, 80#, 100#, 120# |

| Semi-finish grinding | 120#, 150#, 180#, 200#, 240# | |

| Finish grinding | 280#, 320#, 400#, 500#, 600# | |

| Polishing | 800#, 1000#, 1200#,1500# 2000#, 3000# | |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.