Diamond tools for bearing

Moresuperhard can provide:

– Cylindrical grinding wheel

-Centerless grinding wheel

-Double disc diamond grinding wheel

-CBN internal grinding wheel

-Superfinsh oilstone

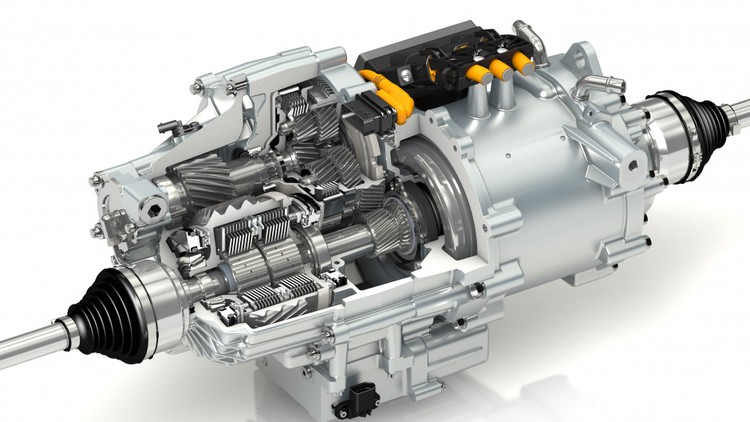

Bearing is an important part of machinery and equipment, bearing main function is to support mechanical rotation body, reduce friction coefficient in the process of movement, and ensure its accuracy. Bearings make a decisive contribution to improving the function of new energy vehicle power systems

Moresuperhard offer full series of products cover the whole bearing manufacturing process, such as bearing inner and outer ring and roller face grinding, centerless grinding, raceway grinding, internal grinding, diamond roller dressing, etc.

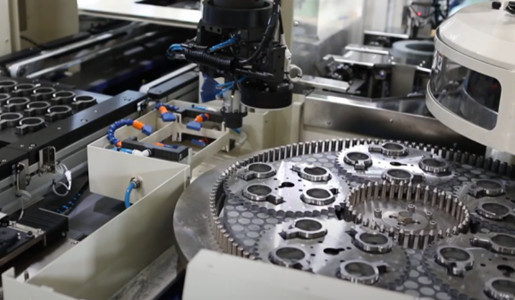

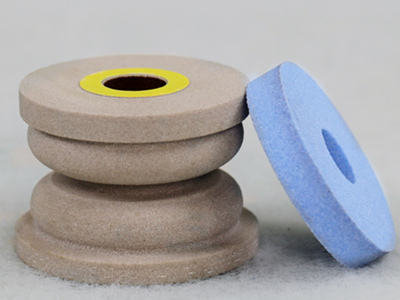

Centerless grinding wheel for bearing ring

The outer ring of the bearing is often processed by centerless grinding. Generally speaking, segmented centerless grinding can achieve very high accuracy. It is mainly divided into coarse grinding, semi-fine grinding and fine grinding. Each stage removes enough margin to ensure that the next stage of grinding does not cause problems such as burns or scratches. The product after fine grinding can reach the dimensional accuracy of the finished product.

Centerless grinding wheel is widely used for Bar grinding, Bearing Race OD ring grinding, Auto part grinding e.g. piston pins, shock absorber tubes & rods, engine valve stems, dowell pins, etc.

Cylindrical grinding wheel for bearing outer track

-outer track

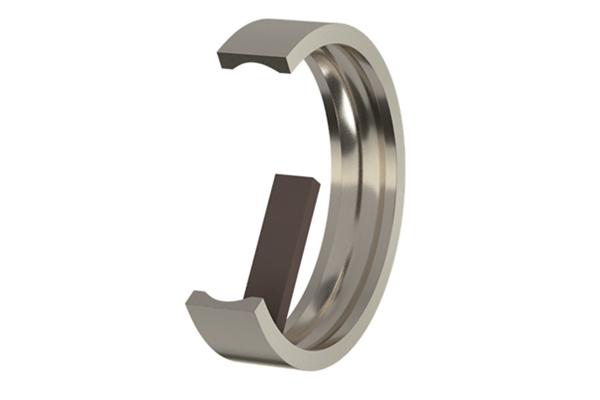

Internal grinding wheel for bearing ring

Vitrified CBN ginding mounted points / grinding wheel /grinding head is widely used for grinding inner surface, special inner surface, inner hole,inner track.

*Application of Vitrified CBN internal grinding wheel:

Suitable for grinding and heat treatment or nitriding after the hardness of HRC45-HRC75 degrees of steel workpiece, such as bearing steel, chromium steel, 45 steel, manganese steel, carbon steel, alloy steel, high speed steel, die steel and so on. CBN internal grinding wheel is widely used in air conditioning compressor, automobile, bearing, machine tool, textile, aerospace and other industries.

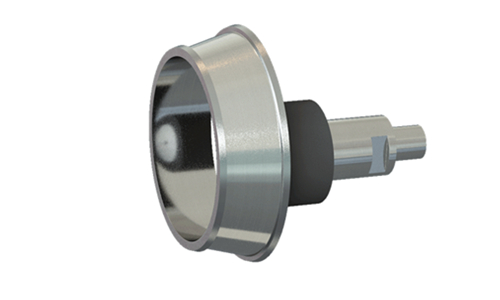

Dressing tools

Diamond roller dressers are used for forming and dressing conventional abrasive grinding wheels and also can be used for dressing CBN wheels.

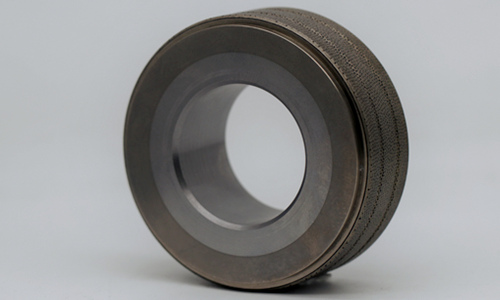

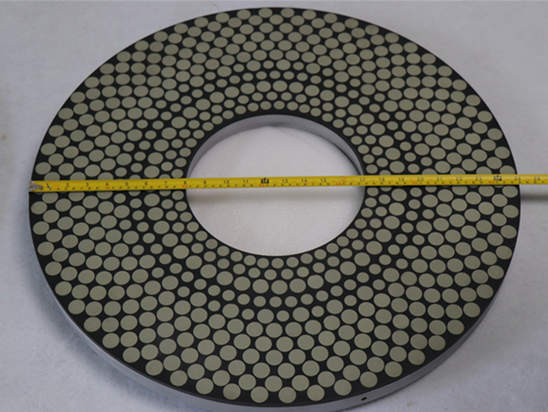

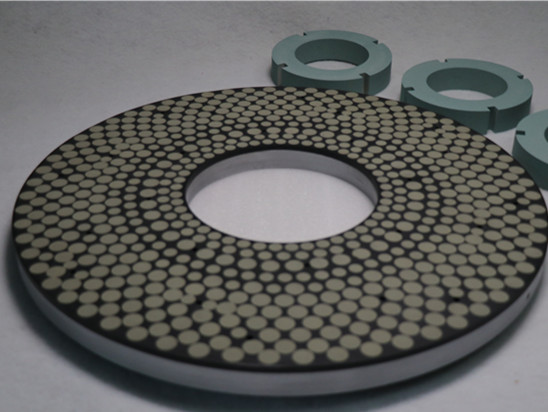

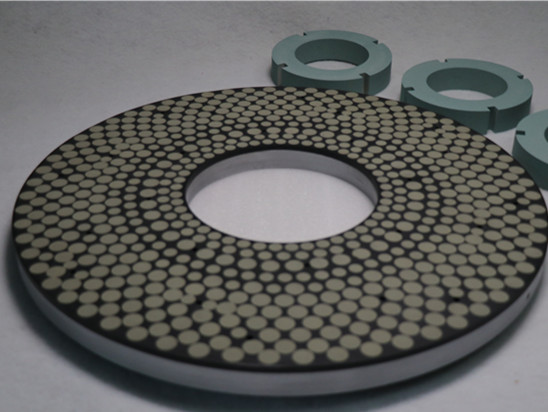

Double disc grinding

Vitrified diamond and CBN double disc grinding wheel are used for grinding bearing end faces, piston rings, gaskets, interstitials, compressor parts, vane pump stator, rotor, blade end faces, semiconductor materials, magnetic materials, tools, precision springs, etc.

Moresuperhard vitrified diamond and CBN double disc grinding wheel for bearing inner and outer ring,taper roller end face grinding.

Matched grinding machine:Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

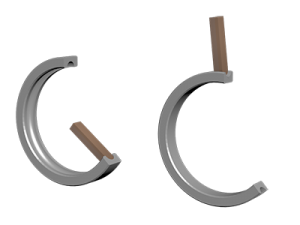

Superfinishing oil stone for bearing track

Super finishing machining, referred to as “super finishing machining”, generally refers to a finishing machining method that can automatically end under good lubrication conditions, in which the workpiece is rotated at a certain speed, the oil stone is pressed on the surface of the workpiece according to a certain pressure, and the reciprocating oscillating motion is made perpendicular to the rotation direction of the workpiece according to a certain law.

The whole process of super finishing includes three distinct stages: dressing, constant cutting and polishing (also divided into cutting stage or self-sharpening stage, semi-cutting stage and finishing stage). And the whole process in the basic process parameters (such as cutting speed, oil stone pressure and hardness, oscillation frequency, abrasive type, workpiece material and lubrication cooling fluid, etc.) under the condition of constant automatically finished.

*Advantages of super finishing

-Can effectively reduce the circular deviation (mainly corrugation), improve the straightness of the raceway bus or produce the desired convex shape.

-Can remove the grinding metamorphic layer and reduce the surface roughness.

-Can make the surface with residual compressive stress, form an ideal cross grain with uniform and fine texture on the machined surface.

-The working contact supporting area can be increased.

-Influence of super finishing on working performance of rolling bearing

-Improve bearing rotation accuracy, reduce bearing vibration and noise.

-Improve the bearing capacity of bearings.

-Improve the lubrication effect of bearing and reduce wear. Reduce the heat of the bearing during work.

CBN superfine oil, can maintain continuous high cutting rate, small wear, high critical pressure, can greatly improve the overall quality and unity of the workpiece processing. Diamond superfine oil can achieve the highest cutting rate, the lowest wear rate and the best surface finishing effect. Cubic silicon carbide whetstone, similar to diamond cubic boron nitride, cutting force and processing quality is second only to the first two, higher than the general silicon carbide.

Application of CBN oilstone:

1. The groove of the inner and outer rings of ball bearings is superfine

2. Tapered/cylindrical bearing/spherical roller bearing inner and outer ring groove superfine

3. Super finishing of cylindrical grinding bearing roller

Case of vitrified CBN oil stone for bearing raceway

| Oil stone customer used before | Abrasive | Corundum oil stone | Cause blockage | |

| Grit | 1000#,12000# | |||

| Workpiece | Bearing raceway | Hardness | 100Cr6 HRC=60 | |

| Surface roughness | Ra=0.1 | |||

| Cutting fluid | Oil-base cutting fluid | |||

| Moresuperhard oil stone | Vitrified CBN oil stone | 3 times life longer than before | ||

Centerless grinding wheel for bearing ring

| Type | Specification | |||

| 1A1 | Diameter(mm) | Hole(mm) | Thickness(mm) | X(diamond layer width) |

| 200 | 75 | 50 | 5,10 | |

| 305 | 120 | 150 | 5,10 | |

| 6A1 | 350 | 127 | 125 | 5,10 |

| 400 | 203 | 150 | 5,10 | |

| 455 | 228.6 | 205 | 5,10 | |

| 9A1 | 500 | 127 | 125,150,200 | 5,10 |

| 600 | 305 | 200,400,600 | 10 | |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.