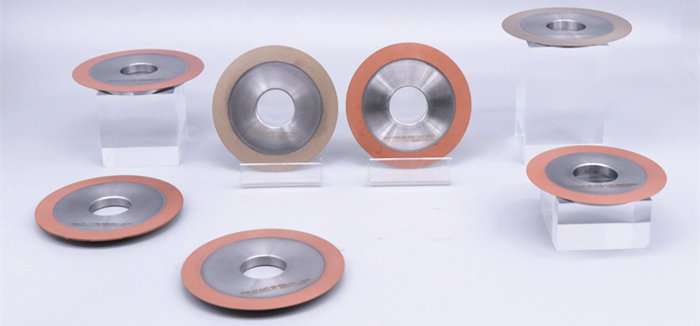

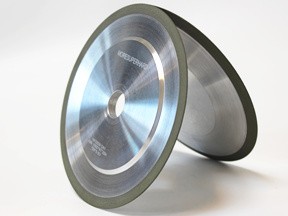

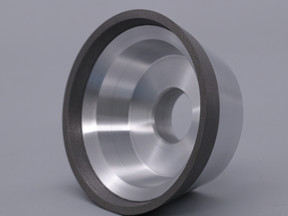

Optical Profile Grinding Wheels

Optical Curve Profile(PG) Grinding Wheel Application: precise grinding mould and die, punch pin, optical grinding and form grinding cutting tool ( such as end mill and reamer) and precise instrument

► Model: 3A1, 14K1, 1B9

► Bonded: resin bond & metal bond

► Optical Profile Grinder: Amada, Waida, Wasion, etc

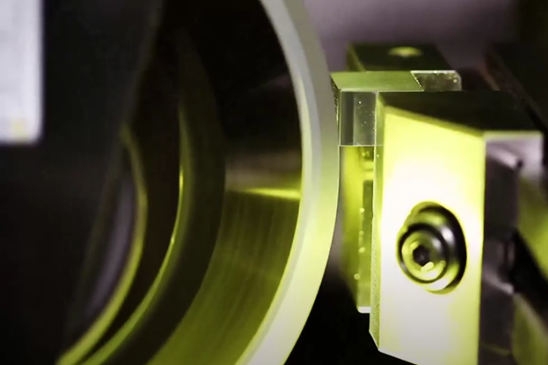

Optical Curve Profile grinding(PG grinding) is employed to grind various precision moulds such as die & punch for press which have complicated forms of irregular lines and curves, forming cutting tools, cutting tools, high precision plate gauge, electrode for electric discharge grinding and formed precision parts such as template.

Structurally optical profile grinding wheels are used in dry, which is a big feature and handled by manual system as well as Numerical Control full automatic system. Lately NC machines are widely employed in various industries and increasing rapidly. Rigidity, horsepower and machining accuracy of latest machines have been much improved where optical profile grinding wheels are required more under this condition to generate high precision machining.

Optical profile grinding wheel is used for precise grinding mould and die, punch pin, optical grinding and form grinding cutting tool ( such as end mill and reamer) and precise instrument.

The workpiece materials:

Diamond:Super hard and brittle cutting materials (such as tungsten carbide, cermets, ceramic, etc)

CBN: heat treated steel (such as SKH, SKD and SKS, etc)

Nose angle and nose strength of profile grinding wheels

Nose angle is available from 5°. Depending on the grit size of diamond or CBN employed, nose width and nose radius change as below. Nose strength is high at wider angle (i.e. an obtuse angle), and is strong against the load given vertically, while it is weak against parallel load.

| Grit Size | 140 | 170 | 200 | 230 | 270 | 325 | 360 | 400 | 600 | 800 | 1000 | 1500 |

| Nose width | 0.2 | 0.18 | 0.16 | 0.15 | 0.14 | 0.12 | 0.11 | 0.10 | 0.08 | 0.08 | 0.06 | 0.03 |

| Nose radius | 0.09 ~ 10 | 0.08 ~ 9 | 0.07 ~ 8 | 0.07 ~ 8 | 0.06 ~ 7 | 0.05 ~ 6 | 0.05 ~ 6 | 0.04 ~ 5 | 0.03 ~ 4 | 0.03 ~ 4 | 0.02 ~ 3 | 0.015 ~ 2 |

Finished Surface

Depending on the grinding conditions, surface finished differs at great deal.

For instance, when you set cross feed at smaller number, particularly good surface can be achieved.(#200MVD=0.5S/1mm/min、automatic feeding)

There are several wheels using abrasives of rough sizes. We recommend you to select a wheel depending on grinding efficiency, precision level achieved, and appearance.

| Grit size | 140 | 170 | 200 | 230 | 270 | 325 | 360 | 400 | 600 | 800 | 1000 | 1500 | |

| Surface roughness S | Metal bond | 4 | 3.3 | 2.8 | 2.3 | 2 | 1.7 | 1.4 | 1 | 0.8 | 0.6 | 0.4 | 0.2 |

| Resin bond | 3.3 | 2.8 | 2.4 | 2 | 1.6 | 1.4 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | |

| Surface finished | Rough | Middle | Precision | Ultra precision | |||||||||

Applicable optical projection grinding machines: WAIDA, WASINO, PROFILTEC, etc

The abrasive grits of profile grinding wheels

| Diamond | For grinding hard materials such as tungsten carbide, cermet, ceramics. |

| CBN | For grinding ferrous materials such as SKH, SKD, SKS, SUS & Etc |

| Concentration(100, 125, 150) | In general we recommend you to choose concentration at 100 or more. |

Specifications of optical profile grinding wheel

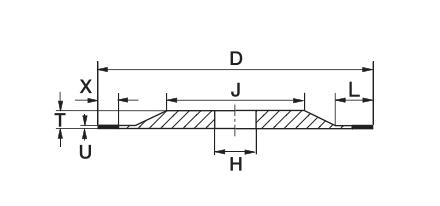

| Model | D | U | X | L | T | H | Grit |

3A1 diamond & cbn wheel |

30-150-180 | 0.5-2.0-5 | 3 | 5-10 | 3, 5, 7, 10 | 4.77

8 12 22.23 24 31.75 32 |

140- 1000 |

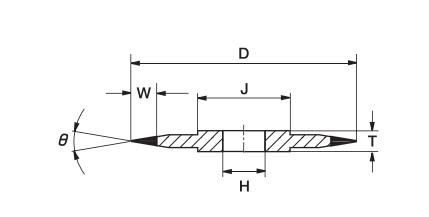

| Model | D | W | θ | R | T | H | Grit |

14K1 diamond & cbn wheel |

30 | 3 | 5°-15°-20° | 0.03-0.2 | 3 | 4.77

8 12 22.23 24 31.75 32 |

140- 1000 |

| 65 | 5 | 5 | |||||

| 75 | |||||||

| 80 | |||||||

| 100 | 7 | ||||||

| 125 | |||||||

| 150 | |||||||

| 180 |

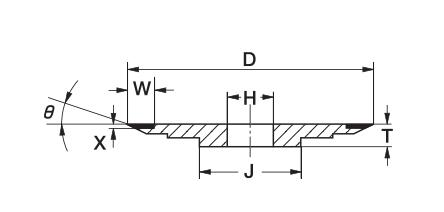

| Model | D | W | θ | R | T | H | Grit | X |

1B9 diamond & cbn wheel |

30 | 3 | 5°-15°-20° | 0.03-0.2 | 3 | 4.77

8 12 22.23 24 31.75 32 |

140- 1000 | 1 |

| 65 | 5 | 5 | ||||||

| 75 | ||||||||

| 80 | ||||||||

| 100 | 7 10 | |||||||

| 125 | ||||||||

| 150 | ||||||||

| 180 | ||||||||

| Other size can be design according to your requirement. | ||||||||

Related Products

-

Back Grinding Wheel for LED Substrate

Back Grinding Wheel for LED Substrate

-

15A2 Diamond Grinding Wheel for Sharpening Carbide Saw

15A2 Diamond Grinding Wheel for Sharpening Carbide Saw

-

11A2 Diamond Grinding Wheel for Sharpening Carbide Saw

11A2 Diamond Grinding Wheel for Sharpening Carbide Saw

-

4B9 Diamond wheels for deep grinding of the cutting face of circular saw blade

4B9 Diamond wheels for deep grinding of the cutting face of circular saw blade

-

11V9 Hybrid Diamond Grinding Wheel for Rotary Tools

11V9 Hybrid Diamond Grinding Wheel for Rotary Tools

-

Peripheral grinding of standard indexable inserts (such as carbide, cermet, PCD and PCBN)

2A2T Peripheral Diamond Grinding Wheel for PCD CBN Cutting tools

-

11A2 Vitrified Diamond Grinding Wheel for PCD/PCBN Tools

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.