Diamond dresser attach with diamond pallets

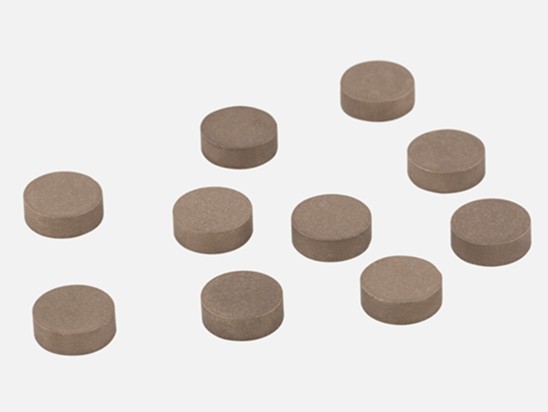

Diamond pallets for precision polishing machine of semiconductor optical chip, and correction of disk surface of 4B-30B various double side machines

Form of inner hole: has round and plum blossom shape.

Type:4B-30B

holding force, high wear resistance, good shape retention, high machining accuracy, high efficiency, good surface quality and long service life.

The diamond pellets or diamond pallets rings are bonded to the matrix material, and the particle size of the pellets ranges from W7 to W40. Mainly used for polishing machine plate polishing sheets(PU sheets) and grinding machine grindstone correction. The matrix materials are usually ductile iron, stainless steel and aluminum parts, etc., .The form of inner hole has round and plum blossom shape.

Application of diamond pellets

Diamond pellet is mainly used for precision polishing machine of semiconductor optical chip, and can be used for correction of disk surface of 4B-30B various double side machines.

How to select grit?

The choice of pellet size in high speed finishing grinding requires both high grinding efficiency and good surface roughness of diamond grinding tools.

– For the first step of fine grinding, it is advisable to use W28 or W20.

– For the second step of fine grinding, it is advisable to use W10 or W7.

– Some special parts may need the third or fourth step grinding, grit they can choose W28, W14, W10, W7, etc

If only one fine grinding step, then W14 is appropriate.

How to select concentration:

Too low or too high concentration of grinding efficiency and quality are adverse. The most suitable concentration is not uniform. Domestic is 30 ~ 50%; Internationally, it’s 45%. Metal binder is widely used at home and abroad in high speed fine grinding.

Shape and dimensions of fine grinding pallets

* Shape of fine grinding plate: generally round, there are also rectangular abroad. While round shape has three forms: flat, convex and concave.

* Size of fine grinding pallets: mainly refers to the diameter and thickness of the grinding pallets. In addition, there are diamond layer thickness and radius of curvature.

* Diameter of the pallets: depend on the radius of curvature of the fine grinding mould, the diameter and the diameter of the wheel disc , while thickness of the fine grinding pallets mainly depend on the diameter of the fine grinding pallets.

| Precision disk radius of curvature(/mm) | 10-20 | 20-30 | 30-50 | 50-150 | 150~∞ |

| surface area of fine grinding disc(/cm2) | 6-25 | 25-50 | 50-150 | 150-1350 | >1350 |

| Size of diamond pellets(/mm) | 4×3 | 6×3.5 | 8×4 | 10×4.5 | 15×5 |

Specification of diamond pellets

| Diameter (mm) | Height (mm) | Diameter (mm) | Height(mm) | Diameter (mm) | Height(mm) |

| 1.5 | 2 | 10 | 5 | 20 | 10 |

| 2 | 2 | 10 | 12 | 20 | 24 |

| 2 | 4 | 10 | 15 | 21 | 5 |

| 2.5 | 1.5 | 11 | 21 | 21 | 15 |

| 3 | 2 | 12 | 3 | 21 | 20 |

| 4 | 2 | 12 | 5 | 23 | 10 |

| 4 | 3 | 12 | 7 | 23 | 18 |

| 4 | 5 | 12 | 12 | 25 | 15 |

| 4 | 12 | 12 | 15 | 25 | 30 |

| 5 | 6 | 12 | 20 | 25.5 | 20 |

| 6 | 2 | 13 | 12 | 26 | 10 |

| 6 | 3 | 14 | 4 | 26 | 16 |

| 6 | 4 | 14 | 5 | 30 | 10 |

| 6 | 12 | 14 | 7 | 30 | 18 |

| 7 | 12 | 14 | 15 | 31 | 12.5 |

| 8 | 2 | 15.5 | 10 | 32 | 6 |

| 8 | 3 | 16 | 10 | 32 | 18 |

| 8 | 4 | 16 | 5 | 32 | 20 |

| 8 | 5 | 16 | 7 | 38 | 29 |

| 8 | 12 | 16 | 18 | 40 | 20 |

| 10 | 2 | 16 | 20 | 54 | 21 |

| 10 | 3 | 17 | 20 | 56 | 28 |

| 10 | 4 | 18 | 24 |

|

Related Products

-

Surface Finishing, Double Disc Grinding Wheel

Surface Finishing, Double Disc Grinding Wheel

-

Vitrified Diamond cBN Double Disc Wheels

Vitrified Diamond cBN Double Disc Wheels

-

Diamond/CBN Double Disc Grinding Wheel for roughing and finishing

Diamond/CBN Double Disc Grinding Wheel for roughing and finishing

-

Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon Wafer

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.