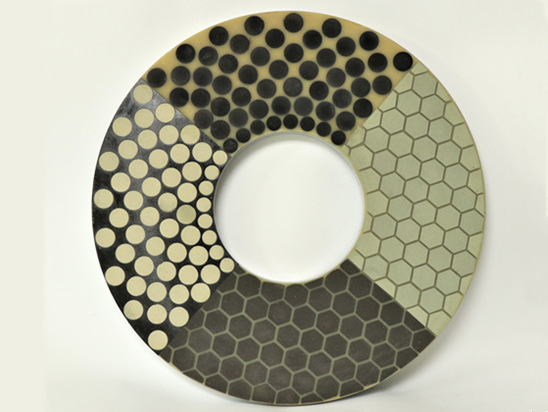

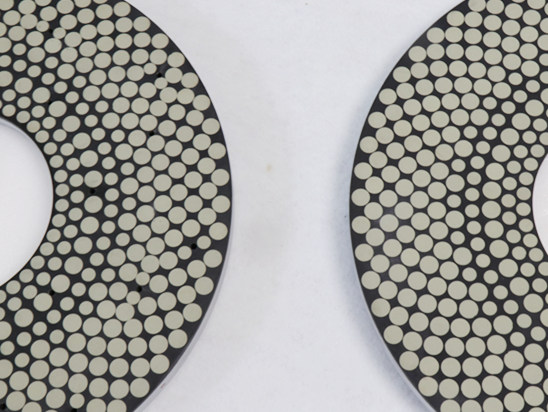

Double disc diamond/CBN grinding wheel for hydraulic parts

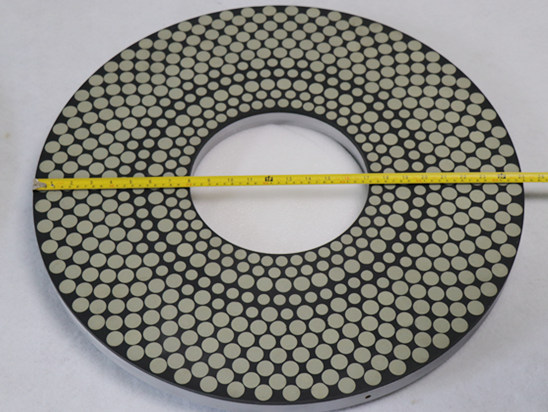

Diameter: 600mm-1500mm

Hole: 200mm-500mm

Thickness: 50mm-100mm

Grit: #100-#1500

For grinding piston rings, gaskets, interstitials, compressor parts, vane pump stators, rotors, vane end faces,etc…

Ceramic bond diamond/ CBN double disc grinding wheel is used for grinding bearing end, piston ring, gasket, interstitials, compressor parts, vane pump stator, rotor, blade end, semiconductor materials, magnetic materials, tools, precision springs, etc.

Applicable fields of double disc diamond & CBN grinding wheel:

♦ Hydraulic pneumatic components. vane pump, conversion valve, piston pump,fuel pump, hydraulic motor parts

♦ Compressor spare parts. air conditioner compressor vane, piston, Refrigerator compressor valve plate, cylinder block (grey cast iron or nodular cast iron), sleeve (alloy cast iron), slide (high speed steel)

♦ Engine parts. automobile fuel pump parts, booster pump parts,oil pump nozzle parts

♦ High precision shaft ,seal, watch parts, molds, carbide blade, ceramic valve core,magnetic materials,etc.

Typical Grinding machine for double disc:

Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

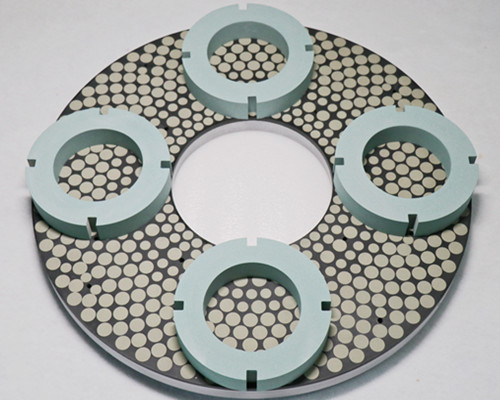

Matching dressing grinding wheel

The dressing wheels are used for dressing diamond and CBN wheels. According to the different particle size, accuracy of the diamond and CBN grinding disc to choose the dressing wheel, making dressing easier and more time saving.

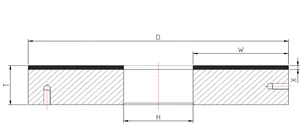

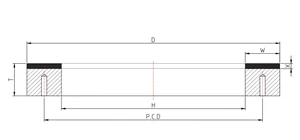

| Drawing | Specification |

1A2T

|

D: 300mm – 1500mm |

2A2T |

W(Abrasive layer width): 40mm – 350mm |

6A2B |

X( Abrasive layer height): 3mm -10mm |

| Flatness:<=2μm, parallelism:≤ 2μm Roughness: Ra0.02μm-Ra0.2μm Durability: grinding HSS slide (25mm*25mm), the number of workpiece ≥ 1million grinding carbide blade, the number of workpiece ≥1million |

|

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.