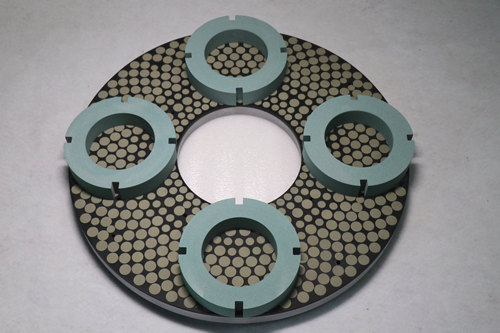

Vitrified Diamond cBN Double Disc Wheels

Application: grinding the surface, suitable for steel, cast iron, copper, carbide,PCD/PCBN inserts, hard alloy, ceramics, monocrystalline silicon and other processing

Bond: vitrified bond & resin bond

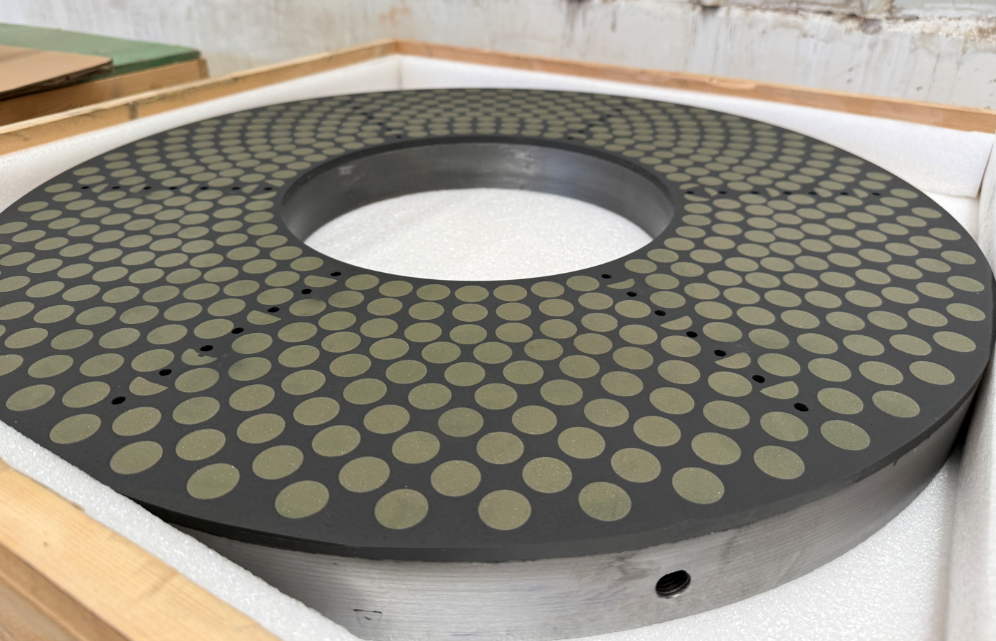

Diameter: 300- 1500mm

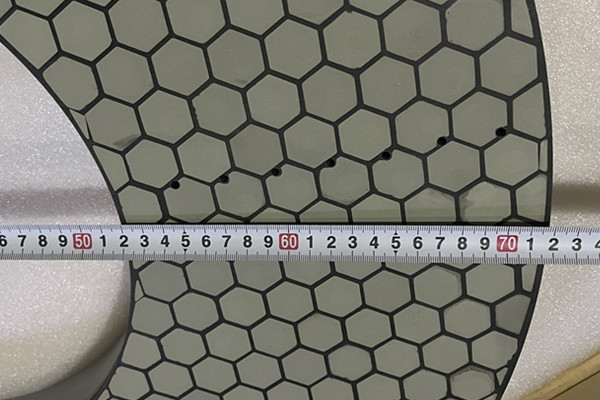

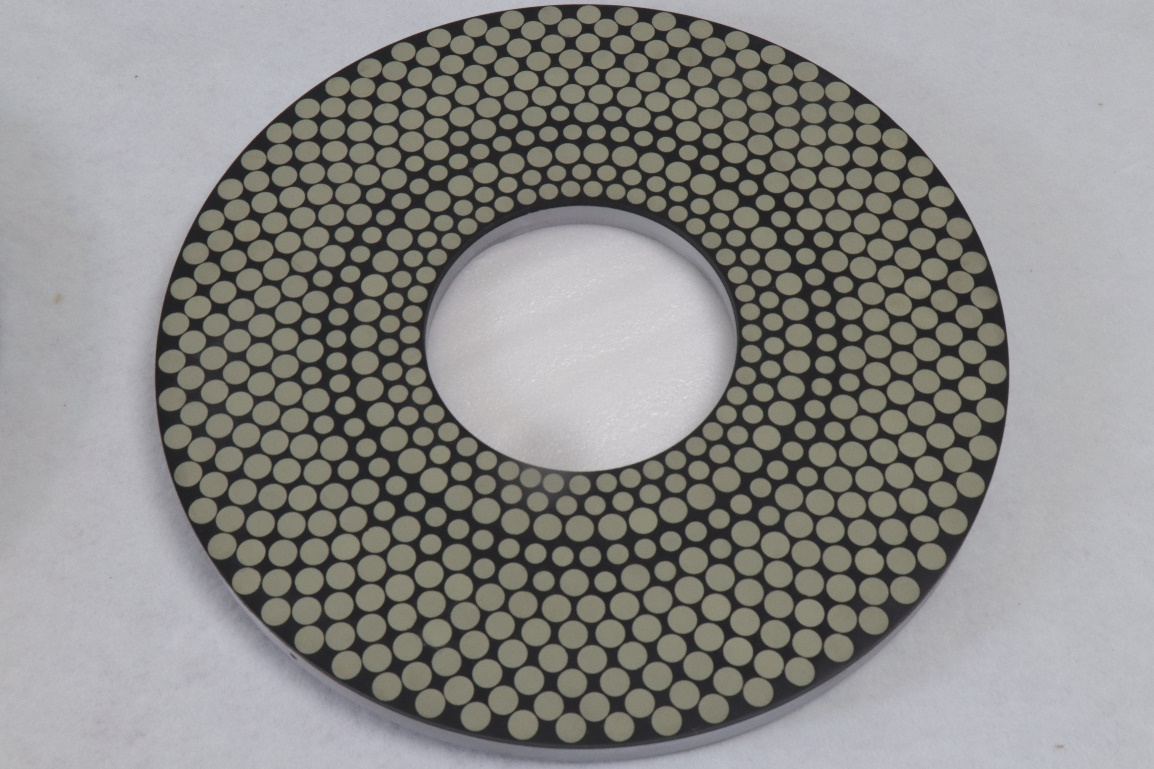

Diamond & cbn shapes: cylindrical, hexagonal, square, segmented

Grinding machines: Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

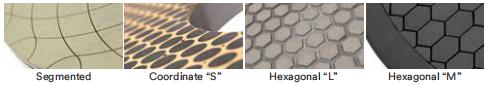

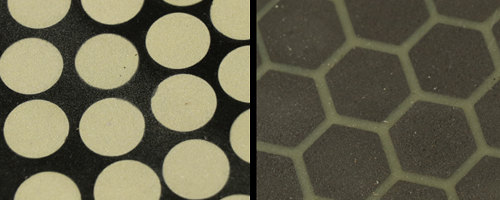

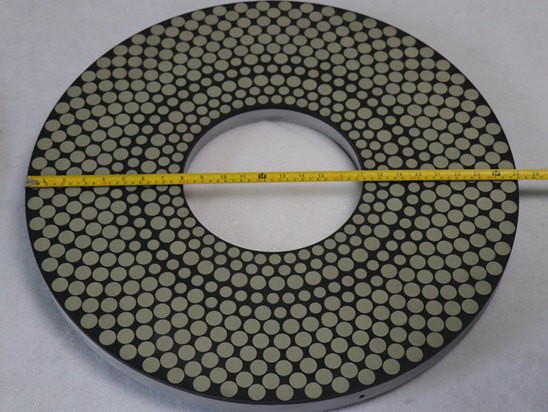

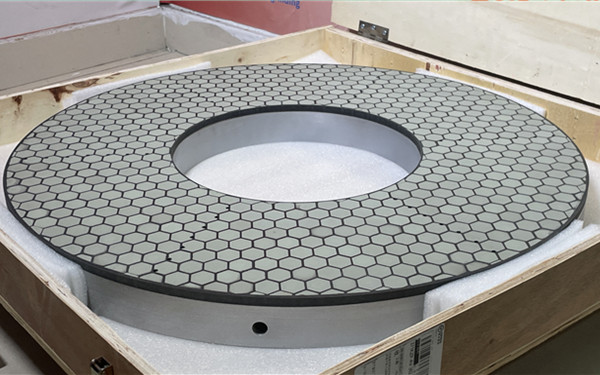

Vitrified Diamond cBN Double Disc Wheels is made of grinding disc matrix and super hard diamond grinding pellets by epoxy resin adhesive, and can be made into various shapes such as

Regular hexagon, sector, square ,circular, trigonometrical, hexagonal pellets (other shapes can be customized).

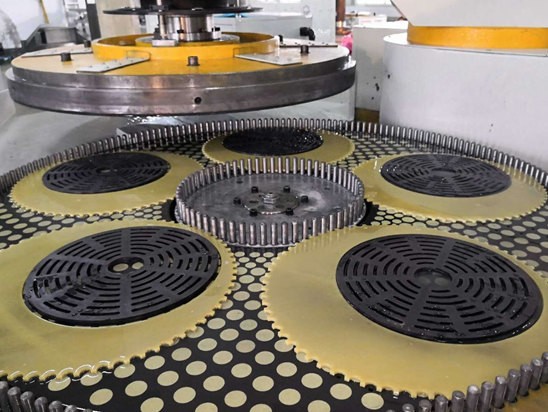

Moresuperhard offers a full line of diamond and CBN double disc grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems.

Vitrified Diamond cBN Double Disc Wheels can be divided into

– vitrified diamond grinding disc (the color of diamond pellets are white and yellow)

– vitrified CBN grinding disc ( the color of CBN pellets are black or brown)

Applications of vitrified diamond cbn double disc grinding wheels

Diamond/CBN double disc grinding wheels are widely used for grinding the surface, suitable for steel, cast iron, copper, carbide,PCD/PCBN inserts, hard alloy, ceramics, monocrystalline silicon and other processing.

Diamond/CBN double disc can be widely used in hydraulic pneumatic components, hydraulic motor parts, automobile fuel pump parts, refrigeration compressor parts, oil pump oil.

Applicable double disc lapping machines: Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other DDG machines.

Moresuperhard can also provide matching dressing grinding wheel of DDG wheel

According to the different particle size, accuracy of the diamond and CBN double disc grinding wheels to choose the dressing wheel, making dressing easier and more time saving. Mostly we use are silicon carbide(GC) dressing wheel while diameter is 205mm, grit 180#.

What is double disk grinding?

Double disc end face grinding technology is a must to find an efficient grinding solution to meet various requirements of the workpieces. A wide range of grinding tasks and a large variety of work, which require more precision and flexibility of grinding itself. The face grinding especially double face grinding is necessary. The Double Disc Grinding process will also produce the highest level of Flatness and Parallelism on opposing surfaces.

Case of vitrified CBN double disc grinding wheel for grinding stainless steel workpiece

| Grinding wheel type | Vitrified bond CBN double disc grinding wheel |

| Size | D1250xH450xT67xt7mm |

| Grit size | CBN 120/140# |

| Workpiece material | HSS, D2 steel, M2 steel, etc |

| Hardness | HRC58-64 |

| Material Removal | 0.5 mm for both side |

| Surface finish request | Ra0.6 |

| Flatness & parallelism | 50 micron |

| Machine type | WENDT |

Case of vitrified CBN double disc grinding wheel for lapping Sintered steel

| Grinding wheel type | Vitrified bond double disc CBN grinding wheel |

| Wheel size | D720xT56xH320mm |

| Grit size | 100# |

| Machine | Lapmaster Wolters |

| Workpiece | Sintered steel (Powder metallurgy) |

| Hardness | 80-84HRB |

| Stock removal | 0.30 to 0.35mm |

| Surface finish request | Ra 1.0 |

| Parallelism | 5μ |

| Flatness | 0.01-0.02mm |

| Dressing wheel | WA dressing wheel |

Case of vitrified CBN double disc grinding wheel for lapping Martensitic stainless steel, heat-treated

| Grinding wheel type | Vitrified bond |

| Wheel size | D1000xT58xH410xt6mm |

| Grit size | Rough 150#, Fine 325/400 |

| Machine | Stahli and Lapmaster |

| Workpiece | Martensitic stainless steel, Heat treated |

| Hardness | 45-50HRC |

| Stock removal | Roughing 0.50, Finishing 0.05mm |

| Surface finish request | N4, Ra<0.4 |

| Dressing wheel | WA dressing wheel |

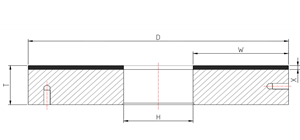

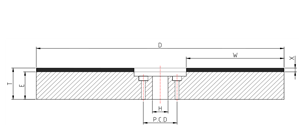

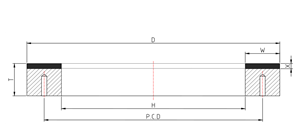

The specifications of vitrified diamond cbn double disc wheels

| 1A2

2A2T 6A2B

|

D: 300mm – 1500mm |

| W(Abrasive layer width): 40mm – 350mm | |

| X( Abrasive layer height): 3mm -10mm | |

| Roughness 0.1um-1.2um,

Flatness:<=2μm, Parallelism:<=2μm, Roughness: Ra0.02μm-Ra0.2μm The number of workpiece >= 1million |

|

Related Products

-

Surface Finishing, Double Disc Grinding Wheel

Surface Finishing, Double Disc Grinding Wheel

-

CBN Disc for Spring End Grinding

CBN Disc for Spring End Grinding

-

Vitrified Diamond cBN Double Disc Wheels

Vitrified Diamond cBN Double Disc Wheels

-

Diamond/CBN Double Disc Grinding Wheel for roughing and finishing

Diamond/CBN Double Disc Grinding Wheel for roughing and finishing

-

Diamond Polishing Paste, Diamond Compound Superfine Surface Lapping

Diamond Polishing Paste, Diamond Compound Superfine Surface Lapping

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.