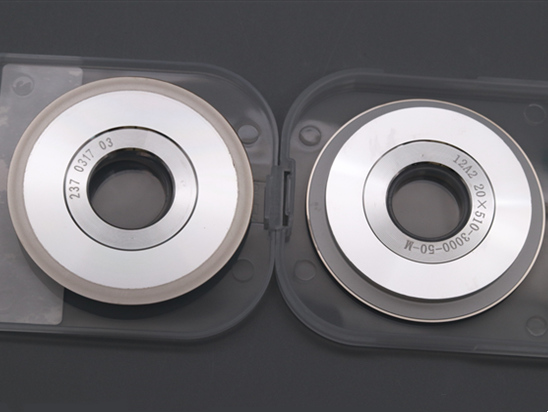

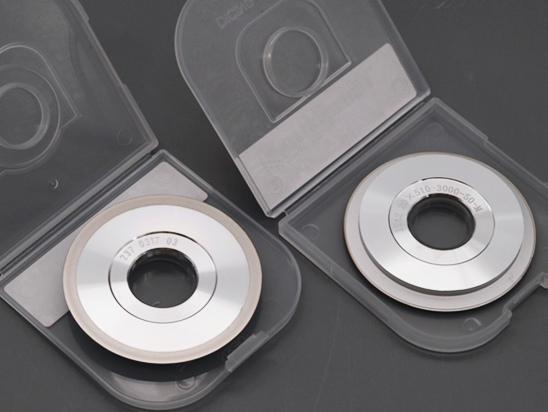

Electroformed Diamond Dicing Blade – Hub Type

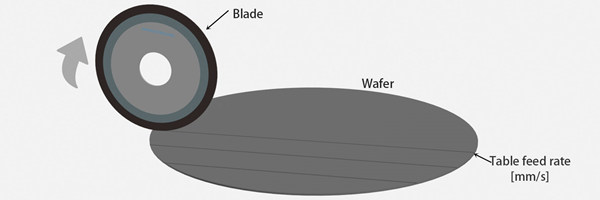

Hub type electroforming nickel bonded dicing blade

Applications: dicing silicon wafers, copper wafer and compound semiconductor wafers such as GaAs and SiC.

Diamond dicing blade is used for grooving ,cutting silicon, compound semiconductors, glass and other materials in electronic information industry. Diamond dicing blade is one of new products developed .Our dicing blades include diamond hub dicing blade and diamond hubless dicing blade.

Applications of electroformed diamond dicing blade

Scribing dicing silicon wafers, copper wafer and compound semiconductor wafers such as GaAs and SiC.

How to selection of the correct types of dicing blades to cut materials

* Binder of resin bond (soft strength) dicing blade, scribing hard and brittle material

* Binder of metal bond (medium strength) dicing blade

* Binder of electroplated bond (hard bond), scribing softer material

Customer Cases

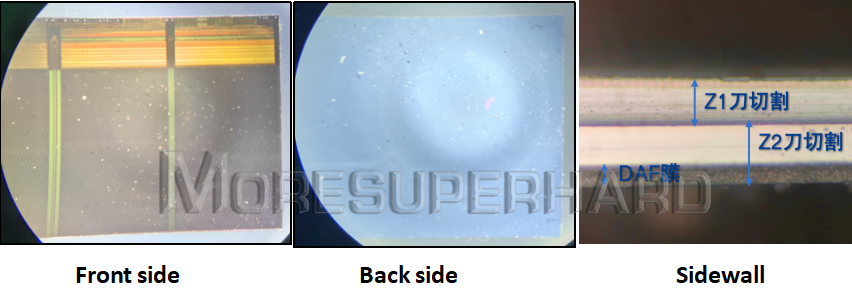

Case of electroformed hub-type diamond dicing blade for dicing wafer

| Dicing Blade: Z1: HD25 CC 4000N70,Z2: HD25 CB 3500N50 | |

| Wafer Type | 8’’ IC silicon wafer, the cutting path contains metal, no laser ablation |

| RotationSpeed of Z1 | 55000rpm |

| RotationSpeed of Z2 | 35000rpm |

| Wafer THK | 220μm |

| InfeedSpeed of Z1 | 60mm/s |

| InfeedSpeed of Z2 | 60mm/s |

Case of electroformed hub-type diamond dicing blade for dicing Oxide wafer

| Dicing blade: HD25 AA 5000H90 | |

| Wafer Type | GaAs, LED |

| Chip size | 98umx98um |

| In feed speed | 20-50mm/s |

| Wafer THK | 150um |

| Kerf width | ≤20um |

| Spindle speed | 40krpm |

| Dicing blade: HD25 DD 2000S50 | |

| Wafer type: | LITAO3, fliters |

| Chip size | 1.2×0.8mm |

| In feed speed | 15-25mm/s |

| Wafer THK | 200μm |

| Street width | 80um |

| Spindle speed | 40krpm |

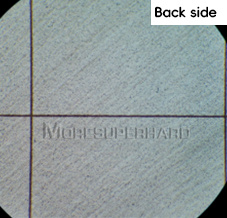

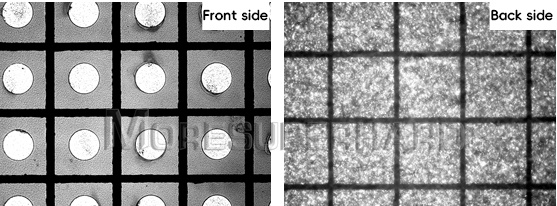

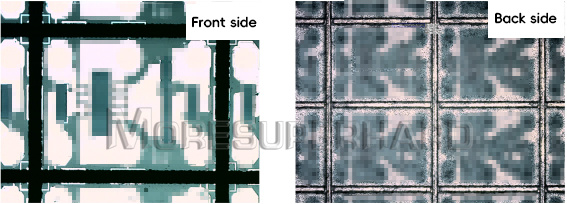

Case of dicing Sic wafer with electroformed hub type diamond dicing blade

| Dicing blade:HD25 BB 2000N50,HD25 BE 2000N50 | |

| Wafer type: | 6’’ SiC,Backside Metallization(Gold) |

| Chip size | 4.5×4.5 mm |

| In feed speed | 5-6mm/s |

| Wafer THK | 180-380um |

| Kerf width | 60um |

| Spindle speed | 45-55K rpm |

If combined with the mid-process grinding technique,it can significantly improve the fracture shown in the figure below, and keep the fracture size below 20um. |

|

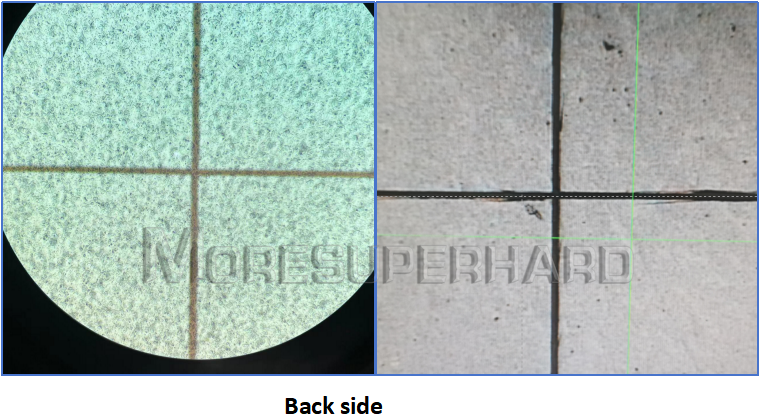

Case of electroformed hub-type diamond dicing blade for dicing Silicon wafer MOSFETs

| Dicing blade: HD25 BB 4000N50 | |

| Wafer type: | Silicon wafer MOSFETs |

| Wafer THK | 150μm |

| Chip size | 0.6×0.6mm |

| Streetwidth | 60um |

| In feed speed | 40-60mm/s |

| Spindle speed | 35krpm |

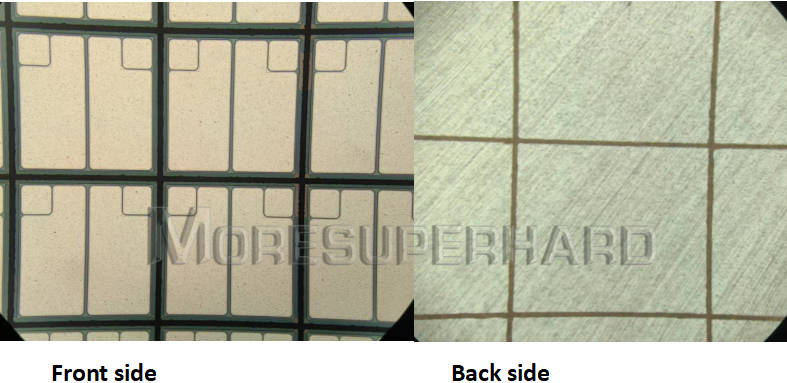

Case of electroformed hub-type diamond dicing blade for dicing GPP chip

| Dicing blade: HD25 CB 2000N110 | |

| Material | GPP:Si + Glass |

| Application | power device |

| Wafer size | 4 inch |

| Wafer THK | 360um |

| In feed speed | 11mm/s |

| Spindle speed | 40k rpm |

|

Quality: Edge Chipping<10um, Backside Chipping<20um, kerf<25um |

|

| Dicing blade:Z1: HD25 CC 4500H70,Z2: HD25 BA 4800H50 | |

| Wafer Type | 12’’ memory wafer (with a DAF film on the backside) |

| Wafer THK | 80um |

| Rotation Speed of Z1 | 50000rpm |

| Street width | 60μm |

| Rotation Speed of Z2 | 45000rpm |

| In feed speed | 20mm/s |

| Requirement: | Edge chipping does not reach the guard ring,sidewall chipping≤30μm。 |

| Result: | Edge chipping≤10μm,sidewall chipping≤20μm。 |

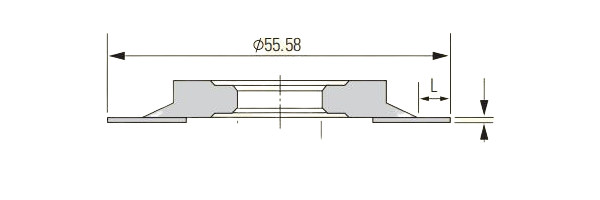

| Exposure(μm) | 380 | 510 | 640 | 760 | 890 | 1020 | 1150 | 1270 | Grit Size |

| Kerf width(μm) | 380-510 | 510-640 | 640-760 | 760-890 | 890-1020 | 1020-1150 | 1150-1270 | 1270-1400 | #5000 #4800 #4500 #4000 #3500 #3000 #2500 #2000 #1800 #1700 #1500 |

| 16-20 | 20*380 | 20*510 | |||||||

| 21-25 | 25*380 | 25*510 | 25*640 | ||||||

| 26-30 | 30*380 | 30*510 | 30*640 | 30*760 | 30*890 | 20*1020 | |||

| 31-35 | 35*380 | 35*510 | 35*640 | 35*760 | 35*890 | 35*1020 | |||

| 36-40 | 40*380 | 40*510 | 40*640 | 40*760 | 40*890 | 40*1020 | 40*1150 | ||

| 41-50 | 50*380 | 50*510 | 50*640 | 50*760 | 50*890 | 50*1020 | 50*1150 | ||

| 51-60 | 60*510 | 60*640 | 60*760 | 60*890 | 60*1020 | 60*1150 | 60*1270 | ||

| 61-70 | 70*640 | 70*760 | 70*890 | 70*1020 | 70*1150 | 70*1270 | |||

| 71-80 | 80*890 | 80*1020 | 80*1150 | 80*1270 | |||||

| 81-90 | 90*1020 | 90*1150 | 90*1270 | ||||||

| Special size can be designed according to customers’ requirement | |||||||||

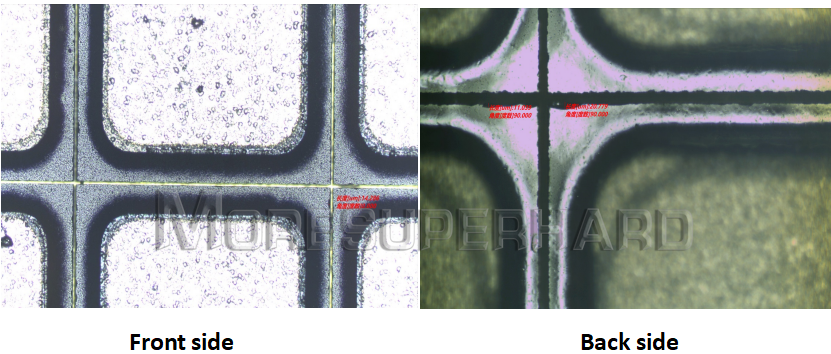

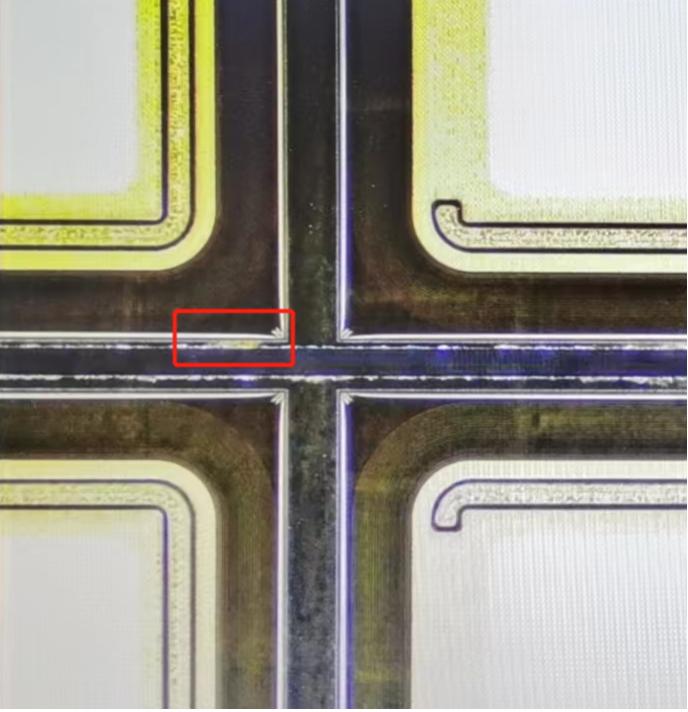

Case of Electroformed hub type diamond dicing blade for cutting wafer

| Workpiece parameters | |

| Wafer Material | LiNbO3 |

| Wafer size | 100mm |

| Wafer thickness | 1mm |

| Chip size | 1.3mm*1.5mm |

| Cutting lane width | 0.08mm |

| Quality requirements: Front chipping size: 0.005mm, Back chipping size : 0.010mm

|

|

Current process parameters:

| Film type | UV film |

| Processed shape | round |

| Speed of mainshaft | Z1=15000rpm |

| Feed speed | 0.5mm/s |

| Blade height | Z1=0.100mm |

| Cooling water flow | 1.5L/min |

Related Products

-

Edge Grinding Wheel, Silicon Wafer Chamfering

Edge Grinding Wheel, Silicon Wafer Chamfering

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

Si/SiO2 Wafer

Si/SiO2 Wafer

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

-

Metal bond Diamond Dicing Blades

Metal bond Diamond Dicing Blades

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon Wafer

-

Diamond Dicing Blades For Wafer Scribing

Diamond Dicing Blades For Wafer Scribing

-

Metal bond diamond cutting wheel , steel core with copper plated is used for grooving and cutting carbide,optics glass, sapphire, ceramics , magnetic materials and semiconductor material

Metal Diamond Wafer Blade with Copper Plated

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.