Electrostatic film belt polishing camshaft,cranshaft

Microfinishing polishing belt

Eelectrostatic aluminum oxide film belt

Electrostatic silicon carbide film belt

Electrostatic diamond polishing film

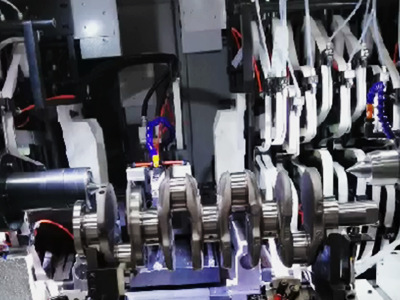

The surface of the crankshaft has high requirements and generally needs to go through grinding and polishing processes. The profile and roughness of the crankshaft are its key indicators. The general profile is guaranteed by the rough grinding of the grinding wheel, while the surface roughness is guaranteed by the precision grinding belt.

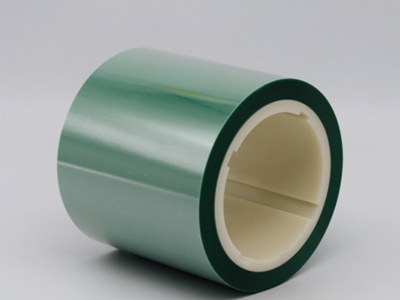

The final finishing steps of camshaft and crankshaft polishing requires precision and extremely tight tolerances.With the help of high voltage electrostatic field force, MORE SUPER HARD electrostatic film belt film plants fine abrasives on the high-strength film, so that the abrasives are uniformly distributed, which can provide higher grinding efficiency and bright and detailed mirror polishing effect. The types of abrasives include aluminum oxide, silicon carbide, diamond, etc.It is suitable for grinding and polishing materials with different hardness, like alloys, ceramics, metals, composite materials and other hard materials polishing.

In the processing of crankshaft abrasive belt polishing, choosing the right abrasive belt is the key to ensure the polishing process. The abrasive belt usually adopts the electrostatic sand planting method, and each sand grain has the best orientation direction to form a sharp sand edge. The cutting process of the abrasive belt is divided into two stages: grinding and polishing.

In the initial stage of processing, the abrasive belt plays the role of grinding. In the compound motion of workpiece rotation and axial displacement, the valleys and peaks of the surface wear marks are smoothed. As the micro-edge of the sand grains is ground, the cutting force increases, the sand grains are peeled off the base belt, and form abrasives with the relatively viscous polishing medium, and the processing is transferred from grinding to polishing stage.

Type and application of electrostatic film belt

| Type | Application |

| Electrostatic aluminum Oxide Polishing Film | * Metal and rubber cylinders.

* Cam and crank shafts. * Metallurgy. * Several finishing processes. |

| Electrostatic silicon Carbide Polishing Film | |

| Electrostatic diamond polishing film | * Automobile parts(Crankshafts, camshafts, balance shafts, fuel injection parts, automatic transmission parts, transfer/mechanical LSD, etc.)

* Carbides and ceramics. * Sintered metals, super alloys and cast materials. * Glass, stone and gemstones. * Composite materials. * Various types of roll polishing * Automobile coating polishing * Flat displays and magnetic heads * Plastic lenses * Optical fiber ends and creation of analytical samples |

Speciation of electrostatic aluminum oxide film belt

| Micron Grade | Color |

| 0.05 | White |

| 0.3 | White |

| 0.5 | White |

| 1 | Green |

| 2 | Teal |

| 3 | Pink |

| 5 | Brown |

| 9 | Blue |

| 12 | Yellow |

| 30 | Blue |

| 40 | Blue |

| 60 | White |

Speciation of electrostatic silicon carbide film belt

| Micron Grade | Color |

| 3 | Gray |

| 5 | Gray |

| 9 | Gray |

| 15 | Gray |

| 30 | Green |

Speciation of electrostatic diamond film belt:

| Micron Grade | Color |

| 0.5 | White |

| 1 | Lavender |

| 3 | Pink |

| 6 | Brown |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.