Gear grinding wheel

Moresuperhard grinding wheels for gear:

* Continuous generative grinding wheel(worm grinding wheel)

* Profile grinding wheel

* Bevel gear grinding wheel

* Ceramic honing rings for tooth flank

* Double disc grinding wheel

* Diamond dressing tools for gear grinding wheel

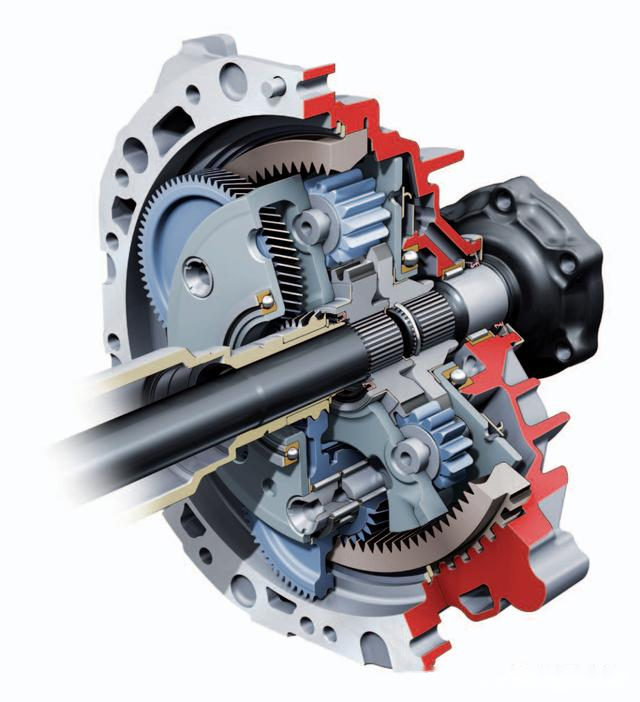

Compared with fuel vehicles, new energy vehicles have stricter requirements on noise, vibration and comfort of the whole vehicle. The multi-speed automatic transmission with high-precision gears plays an important role in improving the power of new energy vehicles, extending the driving range of new energy vehicles, optimizing the performance of the electric drive system assembly of new energy vehicles, reducing the weight and cost of new energy vehicles, and improving the driving experience of new energy vehicles. Therefore, new energy vehicles have higher requirements for the precision and processing quality of transmission gears.

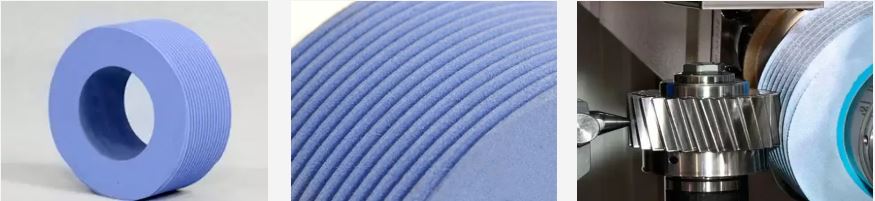

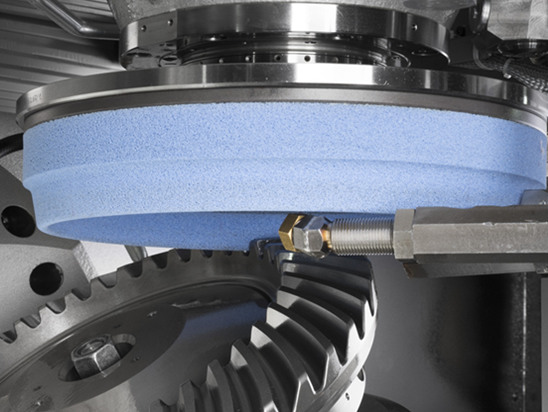

Worm Grinding Wheel for gear

The worm grinding wheel has a high speed and continuous grinding, so the production efficiency is very high. The grinding accuracy is generally grade 5, up to grade 3, which is very suitable for the finishing of gears produced in large and medium batches. The continuous worm grinding wheel is mainly used for grinding the worm gear and worm gear surface of the reducer, so it is widely used for grinding of small and medium size gear, especially the grinding of mass gear.

Moresuperhard worm grinding wheel adopts high-performance ceramic abrasives, which can effectively reduce the grinding force and improve the surface quality. The special pore structure design makes the uniformity and consistency of the grinding wheel better. The excellent shape retention makes the dressing interval of the grinding wheel longer, which can be very effectively help customers improve production efficiency.

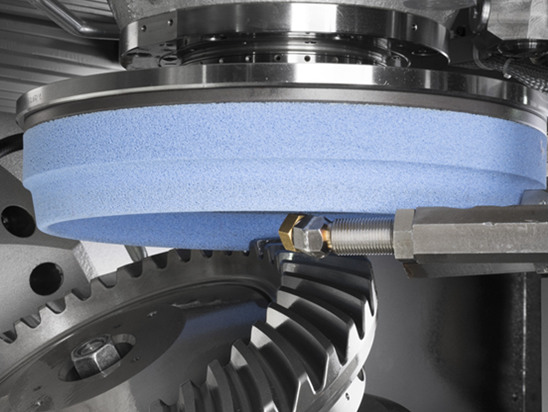

Bevel Grinding Wheel for gear

Cup wheels for grinding bevel gears

High production bevel gear grinding wheel,can effectively reduce gear surface roughness, correct tooth surface curvature, correct contact area, so as to improve meshing transmission. The profile modification of grinding wheel before grinding directly determines the profile of tooth surface after grinding.

Machines:

Klingelnberg, Gleason, Dr. Wiener,ect…

Features:

* Excellent grinding performance.

* Highest wear resistance.

* Less dressing cycles and faster grinding cycles.

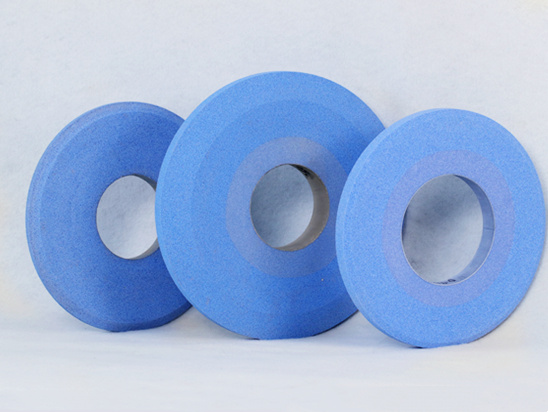

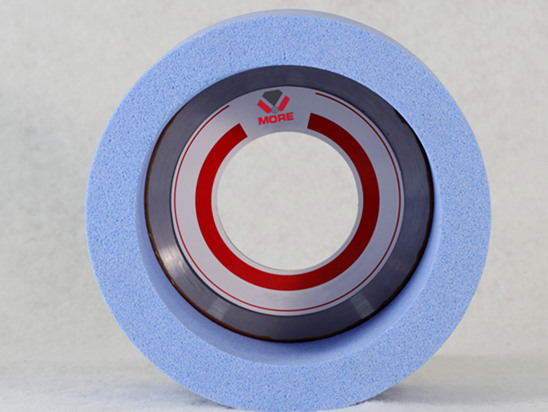

Worm Thread Grinding Wheel/Form grinding wheel

Advantages of Moresuperhard form grinding wheel for gear

* Reduce the grinding force and improve the surface quality

* High uniformity and consistency of the grinding wheel

* Excellent shape retention improve production efficiency

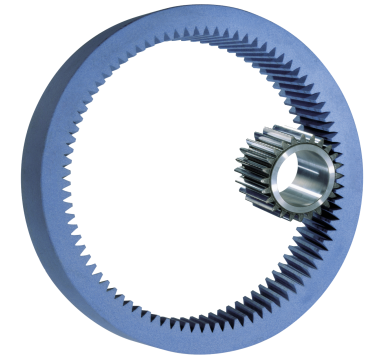

Ceramic honing rings for tooth flank honing

Gear honing is a continuous precision machining process in which the honing tool and workpiece are rolled off each other. Gear honing is to reduce noise in the transmission by changing the surface structure of tooth flanks.

Moresuperhard ceramic honing rings can correction of distortion due to the hardening process, and extended workpiece life.

How to dressing worm grinding wheel

* With the heat-treated hardened steel substrate as the substrate, the surface accuracy of the roller can be maintained for a long time

* The steel substrate of the plated roller needs to be pre-formed in advance on the surface of the steel substrate to be plated. After electroplating and sanding, a small amount of trimming can meet the extremely high tooth profile accuracy requirements, and the damage to the diamond particles is minimal, and the roller has high durability.

* Large amount of abrasive material, sharp edge of the roller, high efficiency of dressing the grinding wheel, and the surface of the grinding wheel has a space for liquid and chip removal, which is not easy to burn the workpiece

* The grinding resistance between the dresser and the grinding wheel is only 1/3~1/2 of that of other process rollers, which can effectively protect the machine tool dressing shaft from damage and loss of precision

* Good transmission stability and low transmission noise.

Specification of worm grinding wheel

| Size | Dimension/Material | Linear speedm/s) |

| 220*180*90 | 3SG80/100JV | 75 |

| 240*230*110 | 3SG80/100JV | 63 |

| 275*160*160 | 3SG80/100JV | 80 |

| 280*160*115 | 3SG80/100JV | 80 |

| 300*125*160 | 3SG80/100JV | 63 |

| 300*145*160 | 3SG80/100JV | 63 |

| 350*104*160 | 3SG80/100JV | 63 |

| 400*100*203 | 3SG80/100JV | 63 |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.