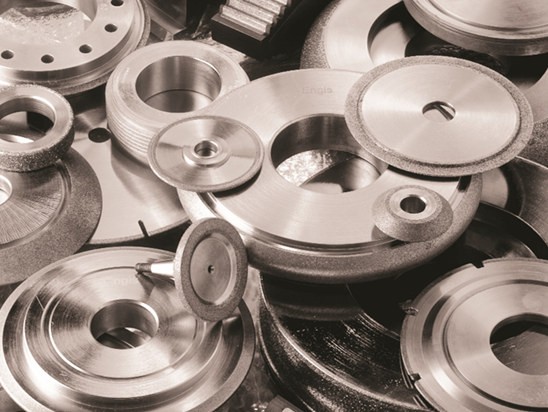

High Precision Electroplated Diamond and CBN Wheels, Plated Wheels

High precision electroplated diamond and cbn wheels

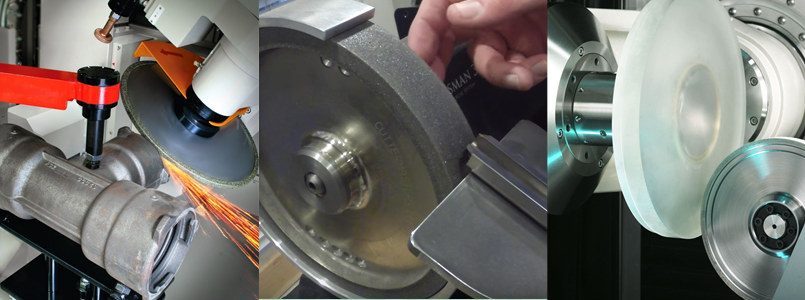

Plated grinding wheels for precision grinding, slot grinding, contouring, scoring, facing and internal or external grinding

Shapes: flat, dish, bowl (special shapes can be design)

Grain size of electroplated diamond cbn wheels

– Rough grinding 80#-100#

– Semi-finish grinding 120#-180#

– Finish grinding 180#-W40

– Lapping, Polishing W40-W100

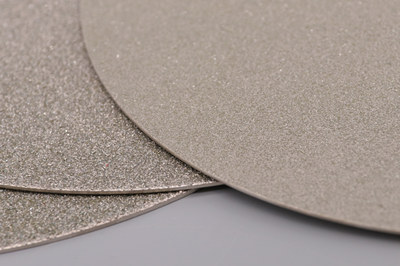

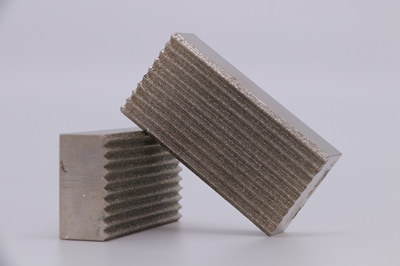

Electroplated diamond or Cubic Boron Nitride (CBN) wheels are made up of a basic single layer or multi-layers (depending on application) of either diamond or CBN particles that are bonded to the tool surface using a nickel matrix. MoreSuperhard provides complete and comprehensive strip and re-plate and reconditioning services. We can assist you in engineering electroplated diamond and CBN wheels for your diverse use.

Applications of electroplated diamond and cbn grinding wheels

– Plated cbn diamond grinding wheels are used for precision grinding, contouring, scoring, facing and internal or external grinding.

– Machining industry: crankshafts, bearings, hydraulic values and etc.

– Electroplated diamond mounted points for dressing the dies made of tungsten carbide and hardened steel.

– Electrical & electronics industry: Electroplated diamond internal and external grinding wheel is the best tool for cutting hard and brittle materials such as a semiconductor.

– Optical glass industry,Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer.

– Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz.

– Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel.

Diamond –

* Carbide (grinding green and sintered tungsten carbide)

* Ceramic (grinding ceramics like SIC, AJO,ZrO, etc)

* Automotive (brake liners and cutting re-enforced rubber mouldings)

* Pharmaceutical (grinding factitious knee joint)

* Dental (profiling rubber bonded grinding pins)

* Ferrite (grinding magnetic parts)

* Chemical (grinding laboratory glass)

* Graphite (grinding graphite parts)

* Glass (grinding tubes, automotive components)

* Fiberglass ,Plastics and Electronic components, etc

CBN –

* High-speed tool steels

* Die steel

* Hardened carbon steels

* Hardened stainless steels

* Alloy steels,Titanium Alloy

* Aerospace alloys

* Abrasion resistant ferrous materials, etc

Advantages of electroplated diamond cbn wheel

-No wheels dressing, Body can be re-plated several times

-High geometric and proportion precision,Complicated forming

-Retain their original shape and dimensions throughout their working life

-Simple electroplated process, less investment convenient manufacturing

-Excellent surface roughness, high grinding efficiency , long tool life

-Cause very little change on wheel shape after used, suitable for precision grinding

Related Products

-

Electroplated CBN Sharpening Grinding Wheels for Scissor, Kitchen Knife sharpening

Electroplated CBN Sharpening Grinding Wheels for Scissor/Kitchen Knife sharpening

-

Electroplated Diamond Band Saw Blades

Electroplated Diamond Band Saw Blades

-

Electroformed Diamond Dicing Blade - Hub Type

Electroformed Diamond Dicing Blade – Hub Type

-

Electroplated CBN Sharpening Wheel for Woodturners

Electroplated CBN Sharpening Wheel for Woodturners

-

Electroplated Flat Lap Diamond Discs of Lapidary Tools

Electroplated Diamond Coated Flat Lap Disc Wheel

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.