Diamond tools for metallographic industry

Cutting: Metal, resin ,electroplated diamond cutting disc

Grinding: resin, metal diamond lapping disc

Polishing: diamond compound, polishing pad, polishing paste, polishing fluid

Metallographic analysis is a method and means to analyze the change law of material properties from the perspective of material microstructure and microstructure. It is one of the important means for material research, material evaluation, product quality control and failure control.

Moresuperhard provide cutting service (diamond/CBN cutting disc), grinding service(diamond lapping disc), polishing service( polishing pad, diamond compound, diamond polishing paste,etc )for metallographic industry.

Cutting

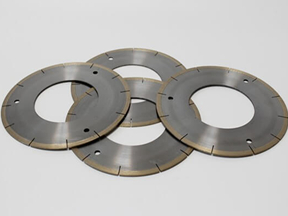

Metallographic cutting discs are used in black and medium hardness products such as stainless steel, carbon steel, tool steel, and powder metallurgy. The performance of the cutting disc is stable. The cutting disc has mastered the material, particle size, density and molding technology of the cutting stone abrasive, so as to ensure that the cutting disc can obtain a good cutting effect from the beginning to the end of the cutting, and can ensure the life of the grinding wheel and cutting efficiency.

Diamond /CBN cutting disc

Metal diamond cutting disc

Metal diamond cutting discs for cutting cutting hard and brittle materials such as ceramics and minerals (> HV 800), manual cutting of minerals and composites with hard phases.

High-concentration metal diamond cutting discs are used for ferrous metals and medium/hard ceramics.

Low-concentration metal diamond cutting discs are used for ceramics, glass and geological samples.

Resin diamond cutting disc

Resin diamond cutting disc ued for cutting extremely hard ferrous metalscemented carbides and ceramics (> HV 800),and also can cut drill tools containing steel and cemented carbides.

Resin CBN cutting discs for cutting extremely hard ferrous metals.

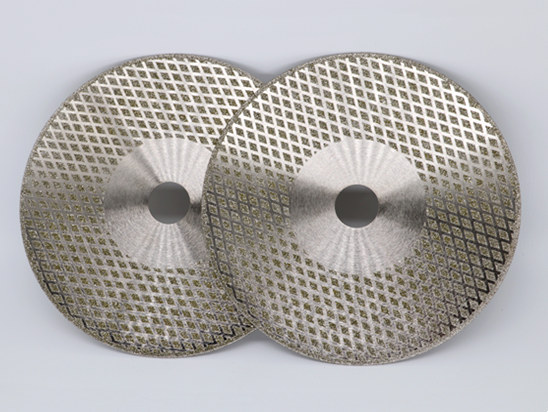

Electroplated diamond cutting disc

Electroplated diamond cutting disc for cutting mounted specimens and parts containing resin or plastic.

Grinding/Polishing

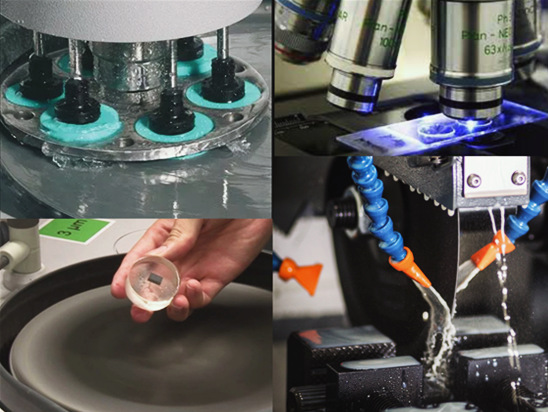

Grinding is the first step in mechanical sample preparation. Proper grinding can remove damage and deformation on the surface of the material while minimizing the introduction of new deformation to facilitate subsequent polishing steps. The grinding effect has a lot to do with the use of equipment and consumables.

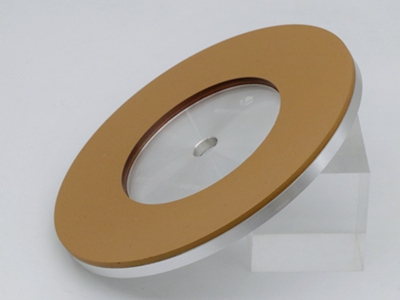

Resin-bonded diamond lapping discs for coarse/fine grinding of harder materials (>HV 150) such as ferrous metals, concrete, ceramics.

Metal diamond lapping discs for coarse grinding of softer materials (HV 40 – 250), such as non-ferrous metals (aluminum, copper, etc.) and softer materials.

Polishing is the further repair of the ground surface before microscope observation. It can control the scratches to one micron or less one by one. It is visually regarded as a mirror surface, suitable for microscopic observation. Due to the different hardness of the sample material, there are different requirements for the polishing cloth.

In order to eliminate the fine damage caused by grinding so that it can be observed under a microscope, the sample must first be polished. Polishing is achieved by polishing cloths with different resilience and different abrasives. It generally consists of two steps: diamond polishing and oxide polishing.

Diamond polishing fluid, is especially suitable for preparing high-quality grinding and polishing surfaces, which can greatly improve your work efficiency, resulting in excellent planarity, edge protection, and reproducibility of results.

Specification of diamond cutting disc

| Size | Product Number | Applicable Materials |

| 100X12.7X0.3 | DIA-100 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 127X12.7X0.4 | DIA-125 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 150X12.7X0.4 | DIA-150 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 175X12.7X0.8 | DIA-175 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 200X25.4X0.8 | DIA-200 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 230X12.7X1 | DIA-230 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 250X32X1 | DIA-250 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 300X32X1.8 | DIA-300 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 350X32X2 | DIA-350 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

| 400X32X2.5 | DIA-400 | Glass,Quartz,Polycrystalline Silicon, Ceramic,Hard Alloy |

Specification of diamond-coated lapping disc

| Outside Diameter (inch) | 4”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 24” |

| Arbor Hole (inch) | 1/2”, 5/8”, 1” |

| Thickness(mm) | 1 – 1.5 |

| Grit (#) | 60, 80, 100, 150, 240, 320, 500, 600, 800, 1200, 1500, 3000 |

| maximum speed (RPM) rating |

2000 – 3000 RPM (6” and 8”) 1500 – 2000 RPM (12”) |

| Other sizes can be design according to customers’ requirement | |

Related Products

-

Electroplated Diamond Cutting disc

Diamond Cutting Disc for Tile Marble, Electroplated Diamond Cutting Wheel

-

Diamond Polishing Paste, Diamond Compound Superfine Surface Lapping

Diamond Polishing Paste, Diamond Compound Superfine Surface Lapping

-

Metal Bond Diamond Cutting disc for Quartz Glass

Metal Bond Diamond Cutting disc for Quartz Glass

-

resin diamond lap disc for Grinding and polishing crystal, gemstone, quartz, glass, agate, sapphire, etc

Diamond grinding discs, diamond lapping discs

-

Electroplated Flat Lap Diamond Discs of Lapidary Tools

Electroplated Diamond Coated Flat Lap Disc Wheel

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.