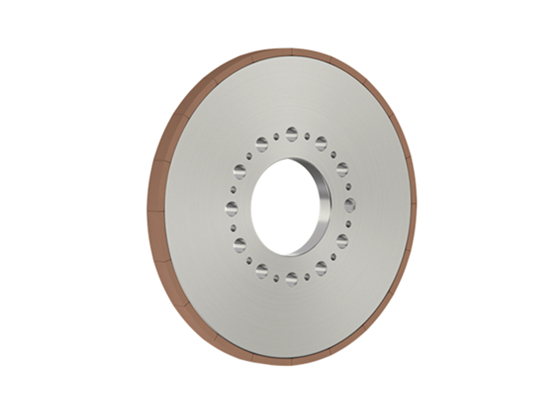

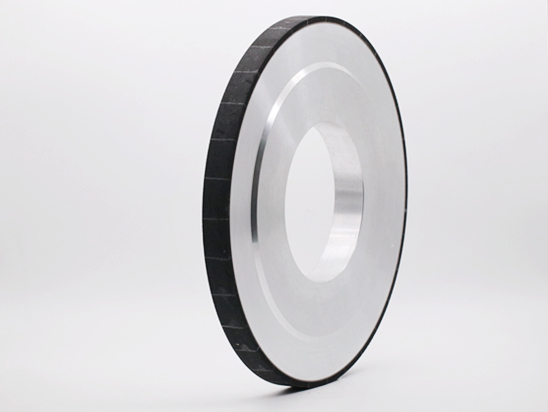

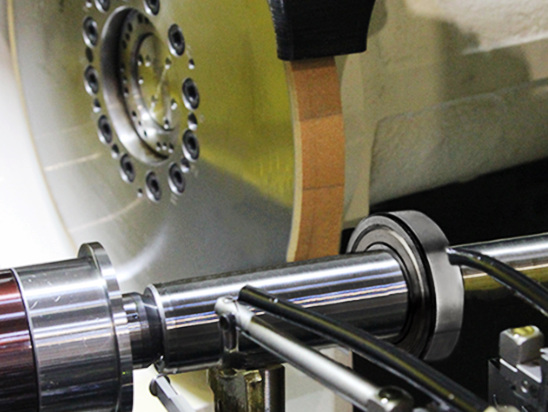

Vitrified CBN grinding wheel can achieve excellent processing effect on motor shafts made of different materials such as high hardness carburized steel, viscous copper alloy and aluminum alloy, and low hardness modulated steel. For motor shafts with a diameter of 4mm-70mm and a length of 10mm-500mm, the roundness of the grinding shaft can reach two microns, the straightness is less than 5 microns, and the surface roughness of the processed workpiece is less than 0.1 microns. Large cutting depth and fast cutting speed, the cutting depth can reach 10 microns

Application of vitrified CBN grinding wheel

Vitrified CBN grinding wheels is mainly used for the precise grinding of the gear shaft and gear, gear inner hole and end face, journal, gear cone, and outer ball grooves.

While meeting gear shaft grinding, multiple ceramic CBN grinding wheels can process different outer diameters at the same time, meeting the grinding accuracy requirements of shaft diameters with different widths. Ensure that the grinding force of each shaft diameter is consistent when grinding, and the shaft diameter can reach a roundness within 1 micron.

Features of vitrified CBN grinding wheel for motor shaft

* High grinding efficiency

* High precision

* Good surface quality

* Easy to dress with an electroplated dressing roller

* Good shape retention

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.