Diamond Rotary Dresser / Profile Roller Dresser

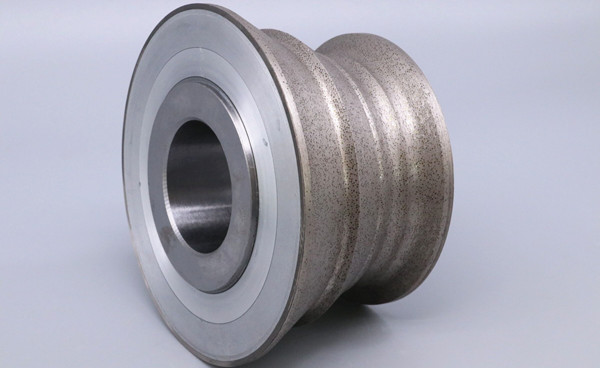

Diamond Rotary Dresser Roller ( profile / form dressing)

Applications: Ball and roller bearings,linear guides, ball screws, gear teeth or racks, turbine industry for grinding the blades,the automotive and -supply industry, general mechanical engineering, etc

High utilization of CNC machine , easy to achieve automation and mass production.

The Rotary dresser is an advanced forming wheel and honing wheel dressing tool with high correction efficiency and can trim complex shaped grinding wheels that cannot be completed by other dressing methods. Epecially those applications using vitrified bonded grinding wheels.

More Superhard diamond dressing rolls are used successfully in the following applications

– The manufacture of ball and roller bearings,for grinding raceway profiles

– Drive technology for manufacturing linear guides, ball screws, gear teeth or racks

– Turbine industry for grinding the blades as well as the blade root and fir tree profiles

– The automotive and -supply industry for grinding camshafts, crankshafts and gear shafts, fuel injection components, piston rings, joints, ball screw drives etc

– Grinding of precision tools such as taps, twist drills, milling cutters, reamers etc

– General mechanical engineering for grinding hydraulic or pump components

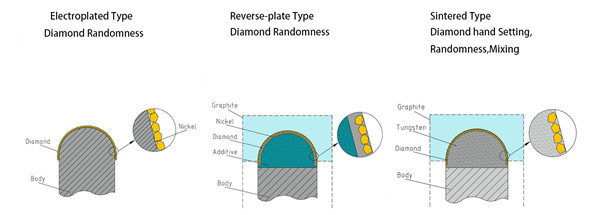

Types of Diamond Rotary Roll

Profile Rolls Profile rotary diamond dressers are used to form grinding wheels for many different kinds of mass production. Profile rolls transfer a defined shape to the grinding wheel rim, which is used to generate the workpiece profile. Usually the profile of the roll corresponds precisely to that of the workpiece but it can also be adapted to the specific grinding. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method.

| Description | Technology | Code | Diamond distribution | Diamond density

|

Accuracy of working surface |

| Profile rolls | Sintered | SD | Hand Setting | Max | Middle |

| Randomness | Max | Middle | |||

| Profile rolls | Electroplated | ED | Randomness | Max | Low |

| Profile rolls | Reverse-plate | RD | Hand Setting | Max | Middle |

| Randomness | Max | High |

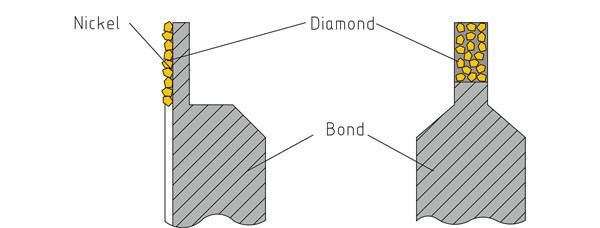

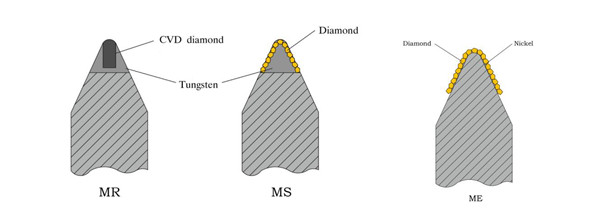

Rotary Dressing Disc The CNC dressing technique can be used in all fields of grinding production, especially for small and medium production lot sizes and for prototype applications. The profile of the grinding wheel is created by the CNC controlled process that moves the rotating form roll along the target contour. Form rolls are therefore not restricted to a specific workpiece but can be used flexibly.

| Description | Technology | Code | Diamond distribution | Diamond density

|

| Dressing disc | Sintered | MS | Hand Setting | Max |

| Randomness | Max | |||

| CVD | Max | |||

| Dressing disc | Reverse-Sintered | MR | Hand Setting | Max |

| Randomness | Max | |||

| CVD | Max | |||

| Dressing disc | Electroplated | ME | Randomness | Max |

Diamond Rolls for Dressing Vitrified bond CBN Wheels The primary characteristics of Vitrified CBN grinding wheel are high hardness, high thermal conductivity, high sharpness, resulting in high grinding efficiency. Suitable for high efficiency grinding of steel. Because CBN material is hard so it is very difficult to dressing, Then special diamond rollers are needed.

Commonly Suitable CNC machine:

Holfer, Gleason-Pfauter, Kapp-Niles, Reishauer, Meccanodora, Samputensili, Cinetic Landis, Toyoda

Performance Characteristics Of Rotary Diamond Dresser

| Runout (mm) | Linearity

(mm) |

Cylindricity

(mm) |

Plainness flatness evenness

(mm) |

Profile tolerance

(mm) |

Dimension tolerance of length and step difference | Dimension tolerance of radius | Angular tolerance |

| 0.004-0.002 | 0.005-0.002 | # 0.005-0.002 | 0.005-0.002 | 0.005-0.002 | L ± 0.004-0.002mm | R ± 0.004-0.002mm | A ± 2 |

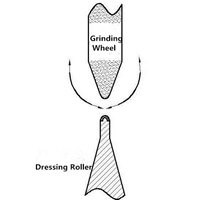

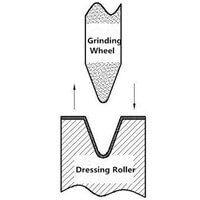

Rotary Diamond Dressers Are Divided Into Profile And Form Rolls

depending on the type of abrasive layer profiling

|

Diamond Profile Dressing Rolls

* Profiling of the grinding wheel along the desired contour by moving the diamond dressing roller * The profile of the grinding wheel is created by a CNC controlled process that moves the rotating form roll along the target contour * Form rolls are not restricted to a specific workpiece but can be used flexibly |

|

Diamond Form Dressing Rolls

* Profiling of the grinding wheel in only one operation using the plunge-cut dressing method * Usually the profile of the roll corresponds precisely to that of the workpiece * Extreme accuracy, even with highly complex profile contours |

Related Products

-

Diamond dresser attach with diamond pallets

Diamond dresser attach with diamond pallets

-

Forming diamond dresser for CNC cylindrical grinding machine, centerless grinding machine

Forming diamond dresser

-

Single Point Diamond Dresser, Diamond Dressing Tools for Grinding Wheel

Single Point Diamond Dresser, Diamond Dressing Tools for Grinding Wheel

-

Diamond Dressing Tools, Dressing Grinding Wheel

Diamond Dressing Tools, Dressing Grinding Wheel

-

CVD Diamond Dresser Roll for Grinding Wheel Dressing

CVD Diamond Dresser Roll for Grinding Wheel Dressing

-

Rotary Diamond Dresser for Ceramic Wheel Dressing

Rotary Diamond Dresser for Ceramic Wheel Dressing

-

Cup wheel for dressing vitrified bond diamond wheel ( Coborn RG9 PCD grinding machine)

How to use cup wheel to dress Coborn RG9 PCD wheel

-

Moresuperhard company developed superabrasive diamond wheel to dressing vitrified diamond pcd grinding wheel.

What dressing tools are used to dress vitrified diamond wheel

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.