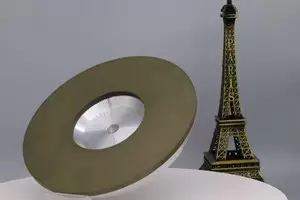

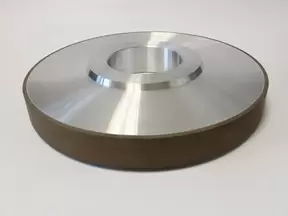

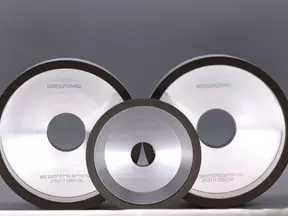

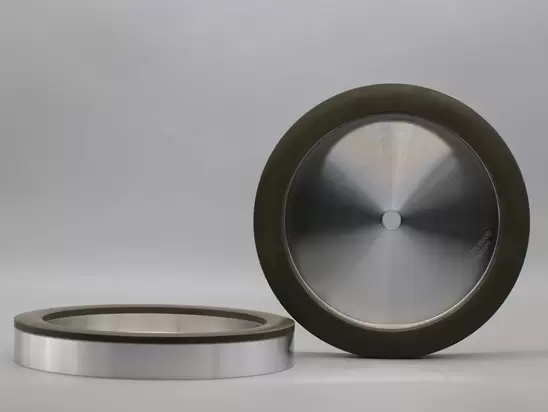

Resin bond CBN grinding wheel for hardened steel

High precision resin CBN wheel are suitable for processing HSS, alloy steel, tool steel, high manganese steel,hardened steel, white steel,etc

Concentration: 50%, 75%, 100%, 125%, 150%

Grit: rough, medium, finish, polishing

Resin CBN grinding wheel is a good choice for grinding hardened steel. Due to cbn grinding wheel with high thermal stability and chemical resistance, the CBN wheel is most suitable for grinding hard ferrous materials, hardened steel, bearing steel, nickel based alloys, machining ferrous materials.

Because of the high hardness of hardened steel is very hard to be grinded. The hardened steel contains the iron element, because of diamond carbon makeup, diamond grinding wheels would often dissolve iron at high temperatures, so it can not use diamond grinding wheel to process hardended steel. CBN grinding wheels doesn’t contain large amounts of carbon, so CBN grinding wheels maintain high levels of accuracy while still removing high amounts of material under extreme heat, making resin CBN grinding wheel has the perfect performance when grinding ferrous metals.

Applications of resin CBN grinding wheels

– Resin CBN grinding wheel can grind most all grades of steel, which have hardness of 45Rc or above, such as grinding die steel, HSS steel, alloy steel, nickel-molybdenum alloy steel, chilled cast iron, tool steel, bearing steel, steel chainsaw, carving chisel, hardened steel,etc.

Moresuperhard can provide vitrified bond, resin bond, metal and electroplated CBN griniding wheel for corase, semi-finish, finish, ultra finish grinding and polishing for hard to process material.

Advantages of Resin CBN grinding wheel

– High-quality raw materials, high purity, sharp and wear-resistant

– High grinding efficiency, long life

– Sharp and fast cutting, high hardness

– Good self-sharpening, full of elasticity and good grinding and polishing performance

– Low heat generation, not easy to block, not to damage the workpiece

– High temperature hot pressed produced, high workpiece precision

– Wet or dry grinding is supprted

Q&A

What is resin CBN grinding wheel?

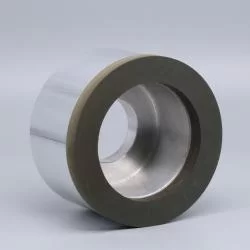

Resin CBN grinding wheel with phenolic resin, polyimide resin, polyurethane resin, and other high performance and new resin as the bonding agent, resin CBN grinding wheel has good self-sharpening and high grinding efficiency.

Why choose CBN wheel?

CBN stands for cubic boron nitride, a superhard material second only to diamond in hardness, cool cutting and the ability to work with ferrous materials, unlike diamond.

Diamond is composed of pure carbon and is produced under high heat and pressure. When Diamond is used to grind hardened steel it causes a chemical reaction and essentially begins to form graphite and lose it strength.

What makes CBN better for working with hardened steels?

CBN is not composed of carbon atoms, instead it is formed with boron and nitride under pressure and heat. Grinding hardened steels produces high temperatures, CBN has a great thermal conductivity, keeping it cool under extreme heat.

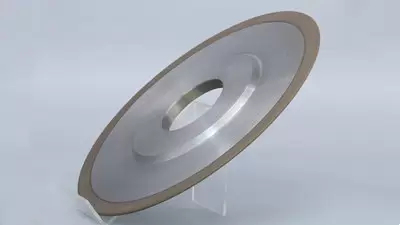

Specification of Resin CBN grinding wheel

| Diameter(mm) | Thickness(mm) | Hole(mm) | X(mm) |

| 150 | 25.4 | 31.75 | 12.7 |

| 175 | 25.4 | 31.75 | 12.7 |

| 200 | 25.4 | 31.75 | 12.7 |

| 250 | 25.4 | 25.4 | 12.7 |

| 300 | 50.8 | 127 | 12.7 |

| 350 | 50.8 | 127 | 12.7 |

| 400 | 50.8 | 127 | 16 |

| 508 | 50.8 | 304.8 | 16 |

| 610 | 50.8 | 304.8 | 20 |

| 750 | 50.8 | 304.8 | 20 |

| 900 | 50.8 | 304.8 | 20 |

| Coarse grinding: 46#, 60#, 80#, 100#, 120# Medium grinding: 120#, 150#, 180#, 200#, 240# Finish grinding: 280#, 320#, 400#, 500#, 600# Polishing: 800#, 1000#, 1200#, 1500#, 2000#, 3000 |

|||

| Other specification can customize according to your requirements | |||

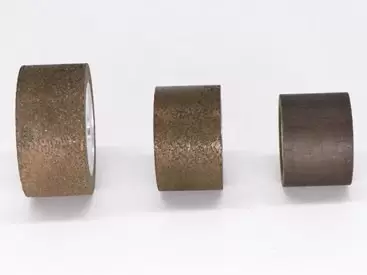

Case 1- resin CBN grinding wheel for hardened steel grinding

| Workpiece | Hardened steel |

| Grinding problems during corundum grinding wheel | Low grinding efficiency and short working life |

| Grinding wheel | Resin CBN grinding wheel |

| Moresuperhard recommend Grit | Coarse grit |

| Feedback | Work well and the life is longer than corundum grinding wheel, get a sharp and long work-life tool |

| How to dressing | Moresuperhard Resin CBN grinding wheel is easy to dressing ( only need one simple corundum stick or wheel is enough ) |

Case 2 – Resin CBN grinding wheel for hardened steel kinfe

| Grinding wheel | Resin CBN grinding wheel |

| Workpiece | industry knife with hardened steel |

| Machine | Goeckel G50 |

| wheel dimension | 6A2 D150x10x6x50 D151 C100 wet grinding |

| Ra require | 0.8 |

| Infeed | 0.09mm/pass |

Related Products

-

Internal Diamond grinding wheel

Resin Bond Internal Diamond grinding wheel

-

Resin bond Diamond Face Grinding Wheel

Resin bond Diamond Surface Grinding Wheel

-

diamond grinding wheel for Needle cylindrical Grinding

Resin bond Diamond & CBN Wheel for Needle Grinding

-

External Grinding Carbide Roll, Resin diamond grinding wheel for HVOF carbide coating

External Grinding Carbide Roll, Resin diamond grinding wheel for HVOF carbide coating

-

Resin bond Diamond Wheel for Tungsten Carbide

Resin bond Diamond Wheel for Tungsten Carbide

-

Resin bond CBN grinding wheel for hardened steel

Resin bond CBN grinding wheel for hardened steel

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon Wafer

-

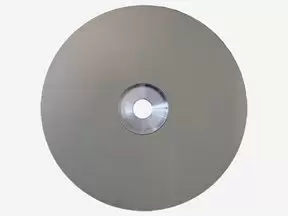

Resin bond Diamond Lapping Disc for crystal, glass

Resin bond Diamond Lapping Disc for crystal, glass

-

Peripheral Grinding tungsten carbide inserts, ceramic inserts, cermet, pcd and cbn inserts

Resin Bond Diamond Grinding Wheel for Inserts peripheral grinding

-

Moresuperhard resin diamond polishing film can achieve consi...

Resin diamond polishing film

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.