Resin Diamond Dicing Blade for Silicon Wafer

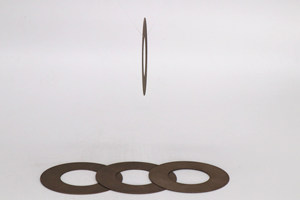

1A8 Ultra-thin diamond dicing blade (over 0.75mm)

Improve chipping, blade life on hard and brittle materials

Applications: glass, quartz, LiTa03 LiNb03, QFN, splitter, sapphire, ceramic, etc

Resin bonded blades have excellent cutting ability that help reduce chippingm fractures, can efficiency improve cut quality and efficiency on ductile and gummy materials such as QFNs and coppers and on hard and brittle materials such as glass and ceramic.

Applications of diamond dicing blade

Resin Bond Diamond Dicing Blades are suitable for cutting scribing glass (optical devices, fiber optics), quartz (optical splitters, saw devices), LiTa03 LiNb03 (devices), QFN (copper epoxy molding ), splitter, sapphire.

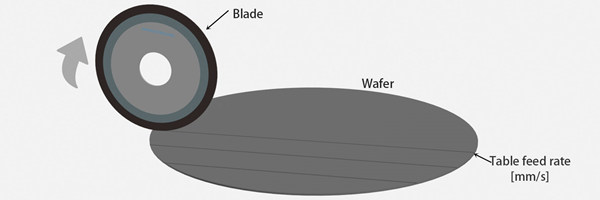

How to selection of the correct types of dicing blades to cut materials

* Binder of resin bond (soft strength) dicing blade, scribing hard and brittle material

* Binder of metal bond (medium strength) dicing blade

* Binder of electroplated bond (hard bond), scribing softer material

| Grit Type | OD (mm) | ID(mm) | T(mm) | Grit Size |

| 1A8 SD / CBN | 50.8 | 25.4 | 0.07 – 0.3 | #200 – #3000 |

| 57.1 | 38.1 | |||

| 50.8-76.2 | 40 | |||

| 101.6 ,114.3 | 69.8 | |||

| 101.6, 114.3, 127 | 76.2 | |||

| 108.1, 127 | 88.82 | |||

| 108.1, 127 | 88.9 | |||

| Special size can be designed depending on customers’ requirement | ||||

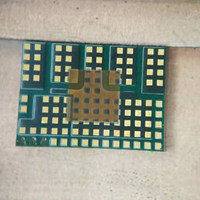

| Workpiece | PCB Material

1.2mm thick resin containing copper layer |

| Dicing Requirements | Cutting without burrs |

| Incision perpendicularity < 0.005mm | |

| Cutting dimensional error < 0.02mm | |

| Snake cutting is not allowed | |

| Dicing / Scribing Machine | Disco DAD3350 scribing machine |

| Diamond Dicing Blade

|

Metal Diamond Dicing Blade |

| 58D x 0.15T x 40H (Grit 400# ) | |

| Cutting Parameters | 1. Cutting direction: Straight cutting

2. Spindle speed: 30000rpm 3. Feed speed: 50mm/S 4. Cooling water: pure water |

| Material | Used to cut a sandwich composite material from 0.2 mm PZT piezoelectric ceramics bonded to 0.127mm stainless steel gasket core |

| Size of resin diamond dicing blade

|

D76.2xH12.7xT0.381mm 60μm |

| Requirement of customer | Cut clean, no burrs, no cracks |

| Test feedback | There are burrs, our surface does not look smooth, diamond sparkles. |

| Measures | Replaced with a fine grit resin diamond dicing blade to test again |

Related Products

-

Edge Grinding Wheel, Silicon Wafer Chamfering

Edge Grinding Wheel, Silicon Wafer Chamfering

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

Si/SiO2 Wafer

Si/SiO2 Wafer

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

-

Metal bond Diamond Dicing Blades

Metal bond Diamond Dicing Blades

-

Electroformed Diamond Dicing Blade - Hub Type

Electroformed Diamond Dicing Blade – Hub Type

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon Wafer

-

Diamond Dicing Blades For Wafer Scribing

Diamond Dicing Blades For Wafer Scribing

-

Metal bond diamond cutting wheel , steel core with copper plated is used for grooving and cutting carbide,optics glass, sapphire, ceramics , magnetic materials and semiconductor material

Metal Diamond Wafer Blade with Copper Plated

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.