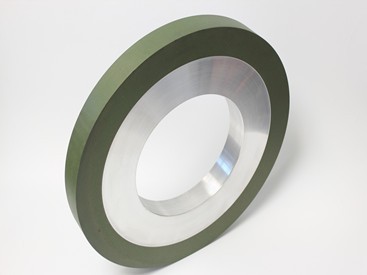

Resin Diamond Grinding Wheel for Carbide Coating

The medium grade is our all purpose, most popular, diamond wheel and will put a great edge on a carbide graver as well as sharpen our carbide spade drills.

Thermal Spray Coating Process

Thermal Spray technologies includ Flame wire spray, Arc spray, Plasma spray, HVOF or HVAF , Detonation Spray, Cold spray .Thermal spraying technology is widely used in aerospace, aviation, machinery, metallurgy, chemical, petroleum, coal, railway, textile and many other departments .

Application fields of HVOF carbide coatings

* Engineering machinery wearing parts

*Wire and cable industry wearing parts

*Metal products industry wearing parts

*Power plant equipment wearing parts

*Petrochemical equipment Customization and repair of wearing parts

More Superhard resin bond diamond wheels on lathe or mounted separately for sharpening tungsten carbide coating, making your own spade drills, for resharpening tools.

The advantages of resin diamond grinding wheel for carbide coating

* The resin bonded diamond surface ensures that they are very hard wearing and leave a beautiful and accurate finish.

* A high concentration of diamond provides a quick cutting surface without vibration so you can spend more time working and less time sharpening.

* 3 grades (grain size ) of diamond wheels: coarse, medium and fine.

The coarse grade is solely used for shaping hard materials and saves time when removing large stock amounts.

The medium grade is our all purpose, most popular, diamond wheel and will put a great edge on a carbide graver as well as sharpen our carbide spade drills.

Fine grade diamond wheel is used for finishing, this is not always necessary but the better the tool the better the finish on your work.

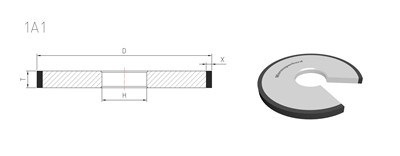

The specifications of resin diamond grinding wheel for carbide coating

| Type | Diameter (inches) | D(mm) | H(mm) | X(mm) | T(mm) | U(mm) |

| 1A1 |

4”

|

100 | 20 | 6 | 12 | |

| 1A1 | 100 | 20 | 10 | 10 | ||

| 1A1 | 100 | 20 | 10 | 12 | ||

| 1A1 | 100 | 25.4 | 10 | 20 | ||

| 1A1 | 8” | 200 | 76.2 | 10 | 25 | |

| 1A1 |

12”

|

300 | 76.2 | 10 | 25 | |

| 1A1 | 300 | 127 | 10 | 25,30,40 | ||

| 1A1 | 300 | 127 | 25 | 50 | ||

| 14A1 | 300 | 127 | 6,10 | 40 | 10 | |

| 14A1 | 300 | 127 | 10 | 40 | 15 | |

| 1A1 |

16”

|

400 | 127 | 10,25 | 25 | |

| 1A1 | 400 | 127 | 10 | 30,40,50 | ||

| 1A1 | 20”

|

500 | 203 | 10 | 15,20 | |

| 1A1 | 500 | 254 | 38 | 25,50 | ||

| 1A1 |

24”

|

600 | 254 | 25 | 25 | |

| 1A1 | 600 | 304.8 | 5 | 40 | ||

| 1A1 | 600 | 203 | 25 | 50 | ||

| 1A1 | 600 | 304.8 | 10 | 50 | ||

| 1A1 | 30” | 750 | 304.8 | 10 | 40,50 | |

| 1A1 | 35.4” | 900 | 304.8,305 | 10 | 50,75 | |

| 1A1 | 36” | 914.4 | 304.8,305 | 10 | 50.8 | |

| 1A1 | 43” | 1100 | 304.8 | 10 | 50 | |

| We can also customized according to your requirements. | ||||||

Related Products

-

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

-

Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

-

Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

-

vitrified diamond grinding wheel used in thermal spraying coating

Vitrified Diamond Grinding Wheel for Hard Surface in Thermal Spraying Coating

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.