CBN abrasive has high hardness, good thermal conductivity and good thermal stability. CBN grinding wheels can be used for high-speed grinding of hard materials such as hot rolling rolls.

As a trusted supplier in superabrasive solutions, Moresuperhard brings industry-specific technology to meet the growing needs of the steel, paper, textile, and non-ferrous rolling industries.

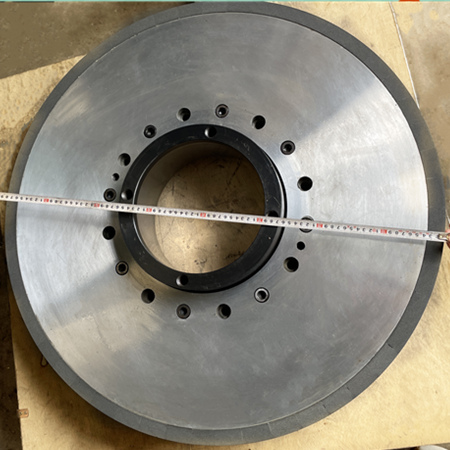

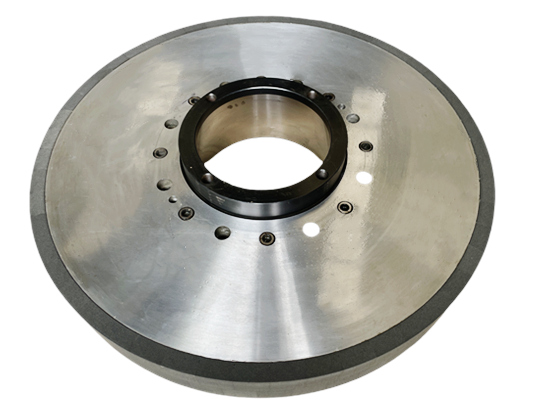

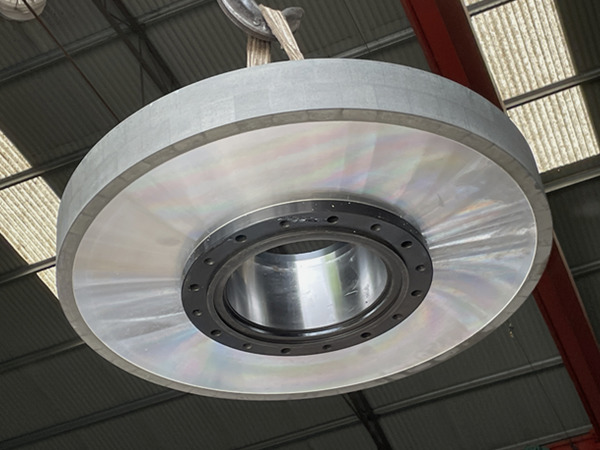

Application of Vitrified CBN Grinding Wheels in Roll Grinding

Vitrified CBN wheels are specially used for grinding:

* Work rolls and back-up rolls in hot/cold strip mills

* Mill rolls in steel and aluminum rolling mills

* Textile and paper industry rolls

* Crankshaft or camshaft rolls

* High-speed tool steel and forged alloy roll materials

CBN is ideal for materials with high hardness (>HRC 45) such as:HSS (High-Speed Steel)

* Hardened bearing steel

* Tool steel

* Chill-cast iron rolls

Why Choose Vitrified CBN over Conventional Abrasive Wheels?

When compared to traditional grinding wheels (such as aluminum oxide or silicon carbide), vitrified CBN wheels offer superior performance and substantial benefits in roll grinding:

1. Longer Tool Life

CBN’s extreme hardness and thermal stability allow for extended wheel life—often up to 10x longer than conventional wheels. This means fewer wheel changes, less downtime, and reduced overall cost per part.

2. Higher Material Removal Rates

Vitrified CBN wheels maintain sharpness under high grinding forces, allowing for aggressive cutting without compromising accuracy. This results in shorter cycle times and higher throughput.

3. Excellent Form Holding and Dimensional Stability

Moresuperhard’s vitrified bond ensures the wheel retains its shape over long grinding runs. Ideal for high-precision applications, it helps achieve tight tolerances and uniform roll profiles.

4. Superior Surface Finish

CBN abrasives provide a cleaner cut with fewer thermal or mechanical defects. This ensures smooth roll surfaces with less need for post-processing.

5. Cooler Grinding Performance

CBN has excellent thermal conductivity, reducing the risk of thermal damage and microcracks in rolls. This is especially important in dry grinding or high-speed operations.

6. Reduced Dressing Frequency

Thanks to high hardness and superior wear resistance, CBN wheels require less frequent dressing, saving operator time and minimizing interruptions.

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.