Vitrified CBN Grinding Wheel for Crankshaft

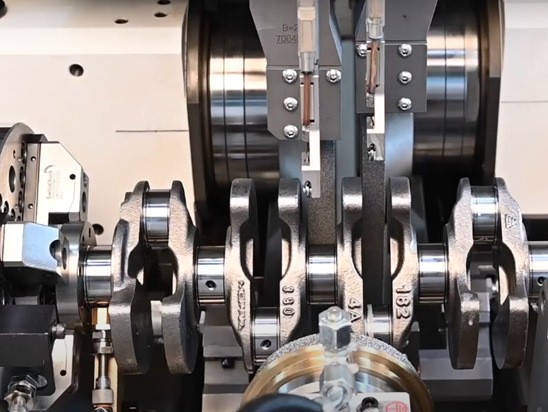

CBN grinding wheel: grinding crankshaft

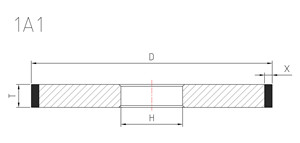

Model : 1A1 CBN wheel

Wheel speed is generally 80m/s-120m/s

High precision and good surface quality

High adhesion strength

Excellent performance

Reduced grinding forces

Easy dressing

Description of cbn grinding wheel for crankshaft

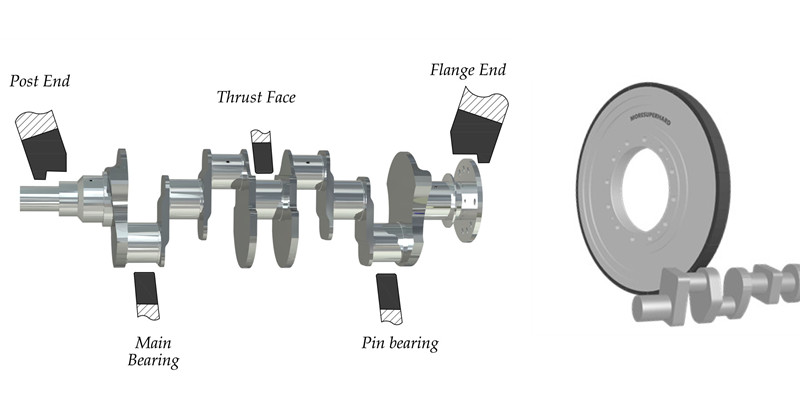

A crankshaft is made up of Main bearings, Pin bearings and Crank webs. A completely smooth journal is essential for motor efficiency during piston ignition of an engine.

Vitrified CBN grinding wheel are remarkable for preventing grinding burns to the shoulder of the Crankshaft. CBN Grinding Wheel For Crankshaft can equip with various high precision CNC Crankshaft Grinding Machines, Suitable for high efficient,heavy grinding of Crankshaft pin grinding,Journal grinding.The wheel speed is generally 80m/s-120m/s.

Solutions for Crankshaft Grinding

Moresuperhard can provide vitrified CBN grinding wheel and vitrified aluminium oxide grinding wheel, Electroplated CBN Wheel for rough,semi-finish and finishc grinding crankshaft.

A type of innovation with the grinding wheels, the crankshaft grinding wheels finds its usage in the different automotive, truck, diesel, aircraft, and small engine manufacturing industry and also in the various engine rebuilding firms that are used to regrind the pins and the bearings.

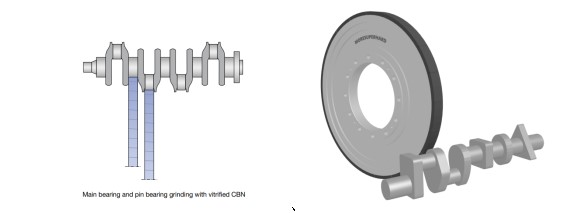

– Main Bearing and Crankpin Journals Grinding with vitrified CBN grinding wheel

Cubic boron nitride (CBN) grinding wheels are used for high production machining of automobile crankshafts.

Applied material

* Cast iron: chilled cast iron, nodular cast iron, grey cast iron, alloy cast iron, etc

* Steel: 20Cr, GCr15, CF53, 45# steel, 55# steel, 80B high carbon steel, etc

Benefits: Long dressing interval = Long tool life, Consistent surface finish and high profile stability, Reduced thermal and mechanical damage to workpiece

Crankshaft Grinding Machines:Ntc, Toyoda, Landis, Mikrosa, Junker, Schaudt, Emag, etc

– Main Bearing Grinding with Vitrified Aluminum Oxide Wheel

When producing small lots or machining larger crankshafts (for trucks and ships), grinding wheels with aluminium oxide abrasives are used.

Benefits of Moresuperhard Vitrified Aluminum Oxide Wheel

-The evenness of hardness and balance performance of the wheels are 30-50% higher than that of China State Standard.

– The thickness deviation of a group of the wheels is not more than 0.2mm.

– The parallel tolerance of two ends is not more than 0.1mm.

Cubic boron nitride (CBN) grinding wheels are used for high production machining of automobile crankshafts

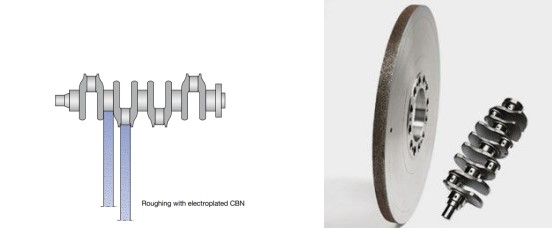

Rough Grinding Main Bearing and Crankpin with Electroplated CBN Wheel

A pin chasing process with electroplated CBN wheels is used for the roughing of the main and in particular the pin bearings of a crankshaft.

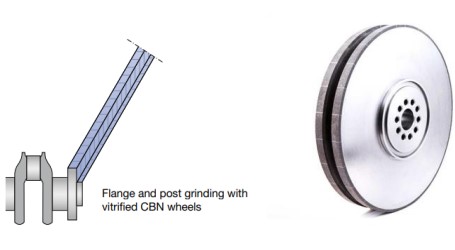

Finish Grinding FLANGE and POST GRINDING

Finish grinding with vitrified bonded aluminium oxide or vitrified cbn wheels.During cylindrical grinding operations for the flange and post it is possible to use different specifications depending on the requirements of the respective contact zones.

Dressing and truing of crankshaft grinding wheels

The dressing and the truing of the grinding wheels: This is mainly done in order to restore the original cutting geometry and to make a final product which is flatter and round. The grinding wheels get their flatness and roundness from the dressing and truing of the grinding wheels.

| Model | D (mm) | T (mm) | H (mm) | X (mm) |

| 1A1 |

500 |

20 | 203 | 5 8 10 |

| 1A1 | 22 | 203 | 5 8 10 | |

| 1A1 | 19.5 | 203 | 5 8 10 | |

| 1A1 |

600 |

35 | 132 | 5 8 10 |

| 1A1 | 19.8 | 132 | 5 8 10 | |

| 1A1 | 20.5 | 132 | 5 8 10 | |

| 1A1 |

650 |

40.5 | 132 | 5 8 10 |

| 1A1 | 43.5 | 132 | 5 8 10 | |

| 1A1 | 44.5 | 132 | 5 8 10 | |

| 1A1 | 50.5 | 132 | 5 8 10 | |

| 14A1 | 600 | 35 | 132 | 5 8 10 |

| 14A1 | 650 | 38.6 | 254 | 5 8 10 |

| Special size can be designed according to your requirement. | ||||

The case of Vitrified CBN Grinding Wheel for Crankshaft

| Application parameters | |

| Work piece | Truck crankshaft:

End face ø90.4mm/Journal outer circle ø74mm |

| Material | 42CrMoA, HRC 52-58 |

| Machine | NAXOS UNION |

| Grinding parts | Journal end face, rounded corners and outer circles |

| Cooling fluid | Oil |

| Grinding way | Cut into the mill |

| Grinding wheel | 1VG1L1 650- -39.6- -6- -3.5 NB151 |

| Dressing wheel | CNC electroplating dresser roller SG 71P-150-1.2 |

| Grinding parameters | Linear speed Vc=95m/s |

| Grinding allowance:

outer circle ae = ø1.2mm, end face ae = ø0.5mm |

|

| Maximum feed speed Vfa = 20 mm/min | |

| Dressing parameters | Linear speed VR=85m/s |

| Dressing quantity aed=15*2+ 1 * 2 um | |

| Dressing speed ratio qd= + 0.89 | |

| Grinding performance

|

Maximum material removal rate Q’wmax = 94.7mm³/mms |

| Grinding time TG = 10 min (40% efficiency improvement) | |

| Dressing frequency

mT=210 journal/Dressing(50%life improvement) |

|

| Roughness Rz<4.5um | |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.