How to do an Efficient Double Disc End Face Grinding ?

Double disc end face grinding technology is a must to find an efficient grinding solution to meet various requirements of the workpieces. A wide range of grinding tasks and a large variety of work, which require more precision and flexibility of grinding itself. The face grinding especially double face grinding is necessary.

Double disc grinding(DDG), also called double face grinding, is a highly efficient method of removing equal stock from opposing faces of a part, normally symmetrical stock removal. The Double Disc Grinding process will also produce the highest level of Flatness and Parallelism on opposing surfaces.

Generally, Double Disc Grinding is used for high productivity however production rates can vary greatly from over 40,000 parts per hour to just a few parts per hour depending on the disc grinders tooling configuration, part size, material, and stock removal.

As we all know, DISKUS developed a kind of new grinding technology named DISKUS Dfined Grinding, this innovative technology allows precise definition of the size, shape and tolerances of the product to be machined; It can machine parallel surfaces with or without steps and it can also define the roughness and grinding style that you want to grind. In the same way, MORESUPERHARD deveopled kinds of double disc grinding wheel to meet the demand of markets.

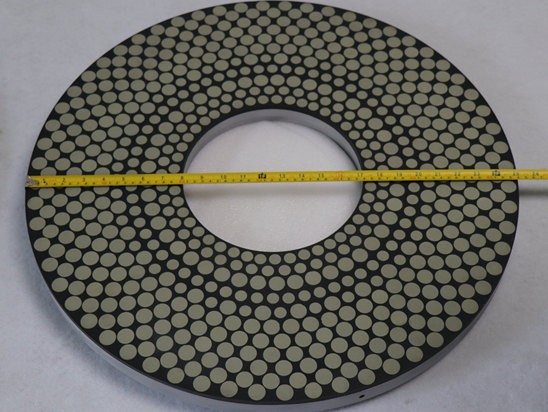

Moresuperhard double disc grinding wheel has been successfully matched with Peter Wolters, Speedfam, AMT, Stahli, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Kemet, Gardner and other brands DDG grinding machine.

Moresuperhard DDG Wheel – the first choice for economical and efficient batch grinding!

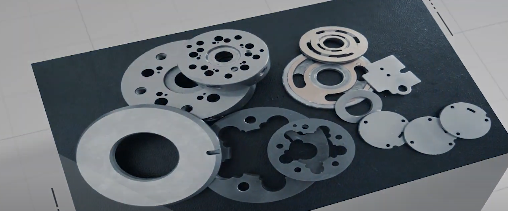

——-Suitable for double face grinding of flat workpiece such as carbide inserts,CBN inserts, ceramic piece, ceramic valves, single crystal silicon, magnetic materials, precision bearing end face, piston ring, washer, caulking piece, precision measuring tool and cutting tool, compressor part, blade, rotor, stator, alloy coating brake disc, etc.

Advantages of Moresuperhard double disc grinding wheel:

1. High Grinding efficiency and long low production cost

2. High flatness, parallelism and perpendicularity

3. Wide application range

It can adapt to flexible production and can process all kinds of metal materials with high processing efficiency, and can grind round and non-round wafer workpiece. Can grind many varieties, small batch of high precision parts with the advantages of high accuracy, fast production and low cost.

4. Workpiece surface finish can get micron level

As a company deeply ploughed in grinding, we can provide you suitable grinding solutions and suggestions according to your grinding application. Wish we can help you achieve real cost savings and increase productivity.

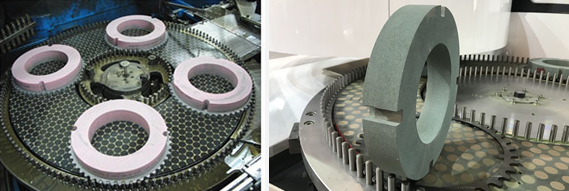

Moresuperhard can also provide matching dressing grinding wheel:

The dressing wheels are used for dressing diamond and CBN wheels. According to the different particle size, accuracy of the diamond and CBN grinding disc to choose the dressing wheel, making dressing easier and more time saving.

If yuo interest, you can contact our sales manager Julia (julia@moresuperhard.com) to know more details.

—EDITOR: Julia zhang/ Doris Hu

—POST: Doris Hu